Portable dining facilities have many benefits over brick-and-mortar buildings, including reduced construction and maintenance costs.

Portable dining facilities have many benefits over brick-and-mortar buildings, including reduced construction and maintenance costs.

In addition to high-performance fabric buildings, Alaska Structures also makes shipping containers to help facilitate fast, easy shipments.

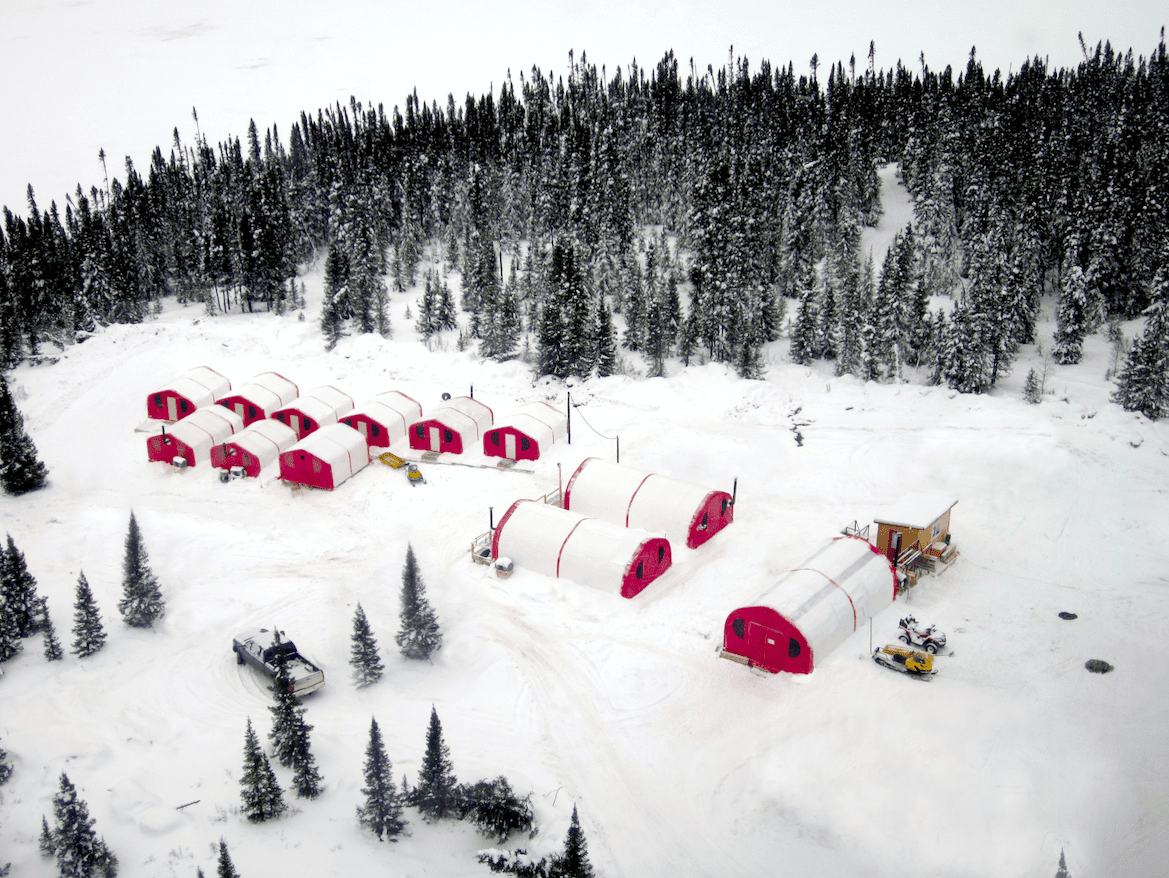

Engineered fabric buildings from Alaska Structures offer mining companies many cost-saving advantages and a versatile multipurpose design.

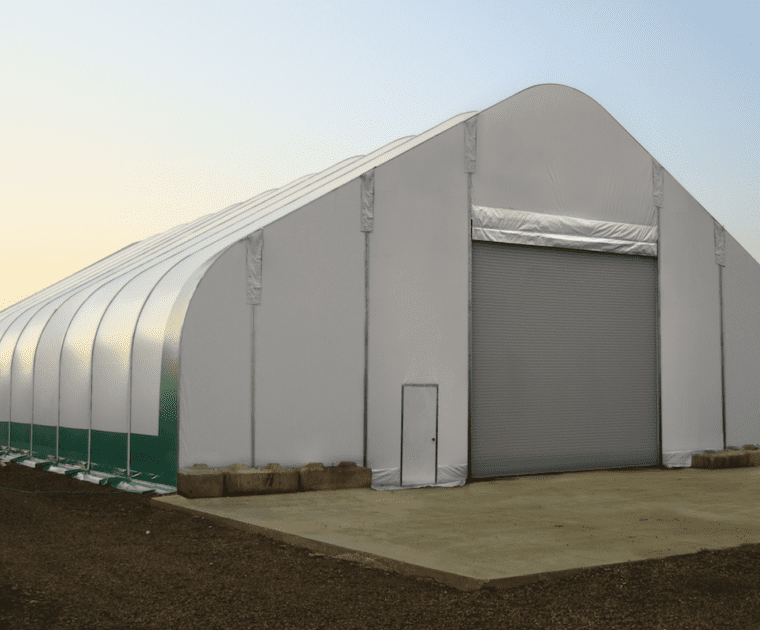

Alaska Structures offers fabric buildings for sale that are uniquely suited for a wide range of commercial, governmental and industrial applications.|Alaska Structures offers fabric buildings for sale that are uniquely suited for a wide range of commercial, governmental and industrial applications.

Promote the well-being of your man camp workers with these health and safety best practices.

Determine whether engineered fabric structures or site trailers are best for your remote mining, oil & gas, or construction operation.

Learn to ensure a high level of worker productivity, as well as attract and retain skilled work crews, and provide a safe and comfortable job site housing.

Alaska Structures manufactures highly durable and versatile tailings pond enclosures to help mining companies reduce the environmental impact of their operations, while providing the necessary protection from the elements.

Though the mining industry has been slower to adopt new technologies, advancements are offering greater ore recovery, and flexibility in mining operations.

Mining is an industry that spans the globe. It places people and equipment in in all environments, often in some of the most remote places, where conditions push the envelope for sustained human activity or survival.

Initiatives and measures for the cleanup and environmental impact reduction of oil and gas exploration are gaining traction, and are largely voluntary.

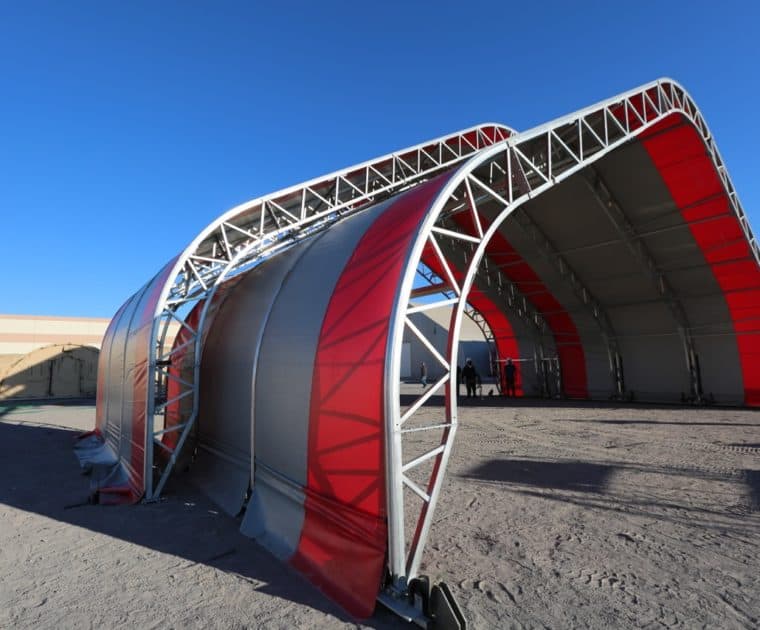

The Alaska Structures rolling system transforms our portable fabric buildings into modular covered workspaces for mining sites, shipyards, and sandblasting shops. Contact us today to learn more!