Now commonly used for temporary and long-term housing and camp systems, quonset huts got their first use as all-purpose buildings for the U.S. military during World War II.

Throughout the war, the army and navy required mass-producible, lightweight buildings for a wide array of applications, necessitating the use of a versatile design.

They also needed to be easy to ship anywhere in the world, and to be set up without skilled labor. Today, this time-tested building design has been integrated with our high performance fabric systems technology, and is available for a nearly limitless array of trade and business uses.

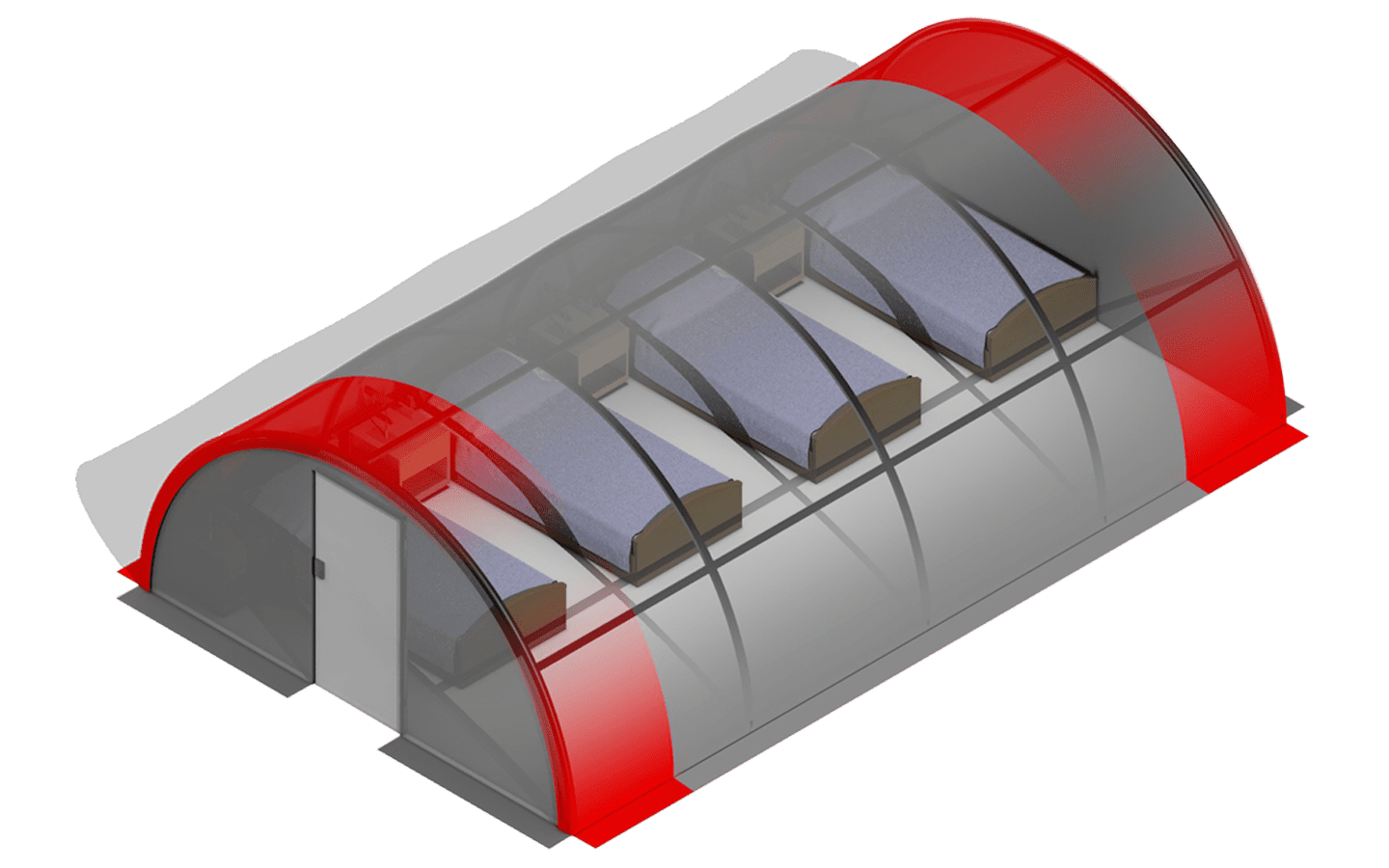

Quonset huts now find use in personnel housing, workshops, and storage facilities. The huts have also been used effectively in other more complex scenarios at mining and research camps, harsh worksites, and many more. There are a huge number of benefits to the quonset hut design, as well as a mix of uses for these fantastically versatile lightweight fabric structures.

Benefits of Quonset Hut Design

All-Purpose Sizes & Shapes

Since we can build these quonset huts in nearly any size and shape, they are very flexible in terms of design. The quonset buildings are for standalone use, or structured to fit into a larger camp system or building layout.

They are ready for use at any length, with the most common width sizes between 15- and 30-feet. However, it’s possible to have wider and other custom sizes. What’s more, the lightweight nature of these huts allows easy growth. You can add more linked buildings as your business grows or space needs change.

Tailored Fittings & Complex Uses

Industrial camps for mining, exploration, and trade efforts are often quite complex operations with costly supplies and precise uses.

While quonset huts are somewhat simple structures, the layout and design is completely tailor-made.

It also houses the complex gear to support fragile and precise operations such as data analysis and even surgery.

High-Strength Design

These types of structures, often built for rough uses, have long-lasting designs to keep up reliability, even in extreme settings.

For example, our SQ Series quonset huts use very strong polyvinyl chloride (PVC) fabrics. The fabric stretches by way of a special tension system over a high-strength, galvanized steel frame.

These buildings, tested and proven in the field, stand strong under heavy snow loads and high winds.

Long-Lasting & Eco-Friendly

Since our quonset huts use strong PVC and galvanized steel, risk of rust and other harmful factors is nearly non-existent. Our structures can serve as fixed buildings for more than a decade, and often even longer.

When used many times for quick jobs, these quonset huts can also withstand many setup and tear down cycles without issue. Therefore, reducing waste destined for the landfill.

The long life of our huts is also due to their eco-friendly traits. For example, the tension fabric covering deflects UV rays to reduce damage from the sun. We also can put on extra coatings to boost its pliancy to weather conditions.

Our systems offer temperature control, power generation and distribution, and LED lighting inside to limit energy waste. From the structural materials, to caulking features and operation systems, we make our quonset huts with an eco-friendly focus. In addition we have more options for less impact to the environment.

Peak Usable Space

With the use of free-span technology, our quonset huts offer the most available inside space.

In addition to the greater capacity for use of space, this benefit allows for effective storage. Oddly-shaped gear and machinery that would normally need a custom building design, can easily fit inside.

Alaska Structures can also make open-ended huts and end walls tailored to go with current structures or meet unique building standards.

Quick & Easy Setup

Quonset hut structures easily and quickly set up, without needing special skills, training or heavy tools. Therefore, build times reduce along with setup cost, adding an extra cost benefit and quicker access to usable space.

Uses for Quonset Huts

In the past, the U.S. military used quonset buildings as military shelters, long term encampments, restrooms, and even post-war housing. Now, these structures have both private and market uses.

Some of the most common uses for these types of fabric buildings include remote camps for mining and research; search camps for oil, gas, and other ore; makeshift, mobile, or permanent housing, and other campsite buildings.

These quonset hut kits arrive on-location ready to use as:

- Storage Buildings to secure and protect gear, machines, supplies, resources, etc. Some of these huts have enough clearance to fit vehicles and other large machines.

- Service and Office Buildings to house research activities, give workspace to workers, and support other worksite actions. Fitted with electrical systems and HVAC, these huts have thorough and comfy workspace.

- Clean, fully usable Emergency Medical Centers for preventative care, injury and illness treatment. Doctors can even do surgery on injured workers.

- Comfortable Housing for singles and small groups who live on-site.

- Lightweight and mobile Crisis Shelters for abrupt needs coming from natural disasters or other crisis.

These cases are only the most common; our quonset hut kits are useful in almost any case.

Alaska Structures specializes in making quonset huts and tension fabric buildings for private, sales, and business uses. We offer average sized huts that are ready-made and ready to ship. There are near-endless options to change sizes and shapes for your own needs.

For more information or if you’re interested in a quonset hut for sale today, visit our SQ Quonsets product page, call +1-907-344-1565, email us, or contact us online.

Leave a Reply