Important considerations before buying a tension fabric building. Try this guide of considerations for industrial and commercial uses of fabric structures.

Important considerations before buying a tension fabric building. Try this guide of considerations for industrial and commercial uses of fabric structures.

Learn about the different modular building applications for construction projects, heavy engineering, power plants and other facilities. These extremely durable and portable engineered fabric structures offer the versatility and cost-effectiveness required for these types of projects.

In addition to high-performance fabric buildings, Alaska Structures also makes shipping containers to help facilitate fast, easy shipments.

Meat processing and packing plants can use Alaska Structures fabric shelters as on-site production facilities to meet increased meat demands.

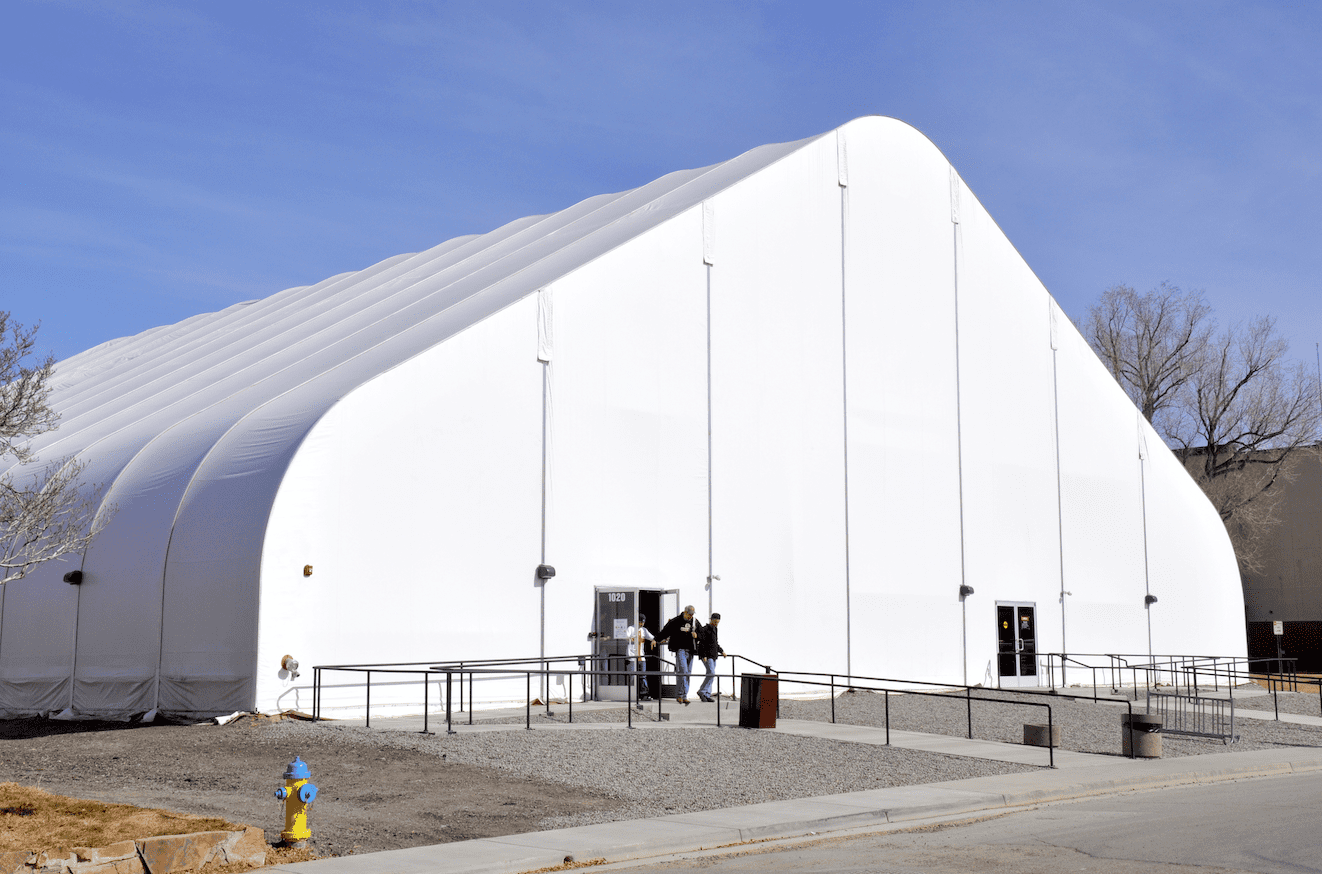

Alaska Structures offers fabric buildings for sale that are uniquely suited for a wide range of commercial, governmental and industrial applications.|Alaska Structures offers fabric buildings for sale that are uniquely suited for a wide range of commercial, governmental and industrial applications.

Learn how engineered fabric structures can help paper mills grow, be more environmentally friendly, and protect employees and products.

Since we use our cars daily to get around, we often forget it is one of the biggest investments we make. Just like any other investment you make, you should protect and secure your car. Instead, a lot of us park outside leaving our cars in the elements and susceptible to damage. If you don’t have a garage or it full of equipment so you can’t fit your vehicle inside, a fabric carport is a good option for you. The benefit of using a fabric carport is that it is cost-effective, easy to install, easier to enter your car, portable, and protects the car from the elements. Learn how fabric carports accomplish these objectives to help stop your car from depreciating so quickly.

COVID-19 has dramtically affected businesses & manufacturing. Learn how creating an efficenty production facility can help your business.

Alaska Structures offers long-lasting building systems to exceed expectations with building solutions for engineering and architecture firms. Learn more!

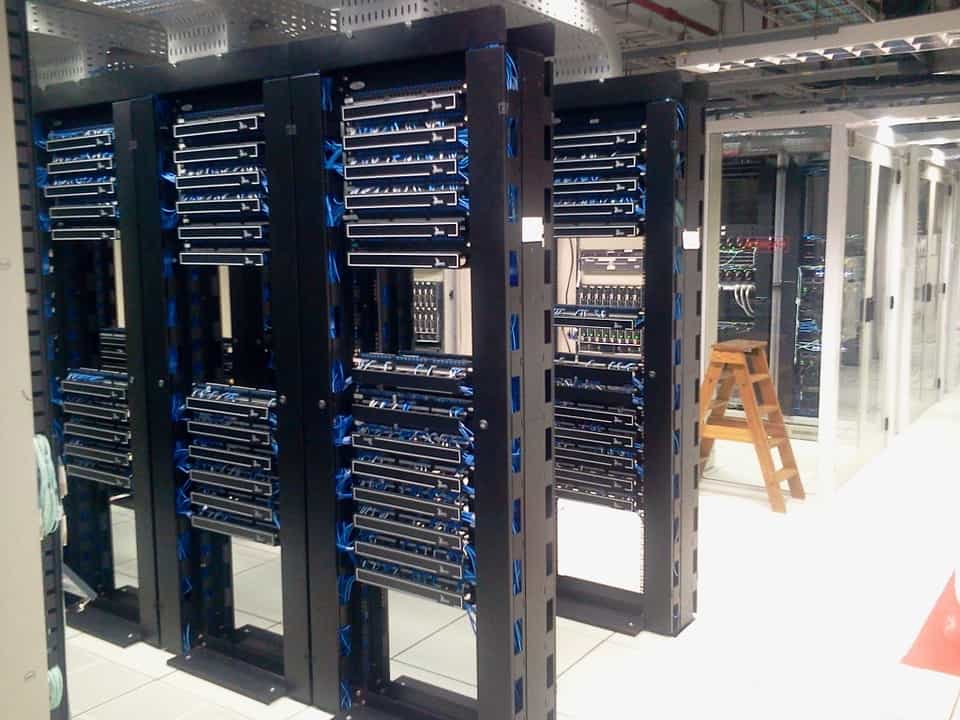

Choose efficient & affordable building options for your data center or server farm. Learn how a fabric structure can be your solution.

Engineered fabric buildings have helped the timber industry increase efficiency by protecting their machinery and provide lodging for workers.

As a construction material, concrete can be used in a variety of applications. Special considerations must be made for its storage during the winter.