With winter approaching, the construction industry faces weather challenges, such as how the cold and wet affect equipment and supplies. Job progress can’t stop when the rain starts and temperatures plummet. One such weather-sensitive material that needs special consideration is cement.

Cement is primarily calcium, silicon, aluminum, and iron derived from grinding various rocks and other materials. Water activates the hardening process that turns cement into a solid mass. The material is so absorbent that you should not expose cement to the air, which contains water vapor. Storing cement and cement products, such as concrete, involves careful placement and proper protection of the material.

The Environment Protection Agency (EPA) suggests the following practices, which will help reduce construction and demolition waste:

- Preserving existing buildings when feasible

- Designing versatile buildings that can adapt

- Using materials that can be disassembled and reused

- Using alternative framing technology

Protect Your Cement with Fabric Buildings

Project managers and concrete plant operators have to find ways to manage the challenges that winter weather brings. Rain, snow and cold temperatures can all affect the performance of cement and cement products. You will want to protect your cement materials to ensure that you maintain cost-effectiveness while delivering the highest-quality product possible.

Design a Cement Structure to Keep Moisture Away

If stored cement gets wet before the intended use, the result may be a weaker product. The cement storage facility should be waterproof and be kept dry. Doors should be located on the leeward side of the building to prevent unwanted water penetration. If you are going to build a cement storage structure with windows, special consideration should be given to ensure the windows will not leak.

The flooring for cement storage should be raised to clear the ground to allow airflow and to prevent moisture seepage. The entry should slope toward the exterior, so water cannot accumulate and come into contact with the stored cement.

Cold Weather Concreting

Pouring concrete in cold weather can be a challenge. At temperatures below 50 degrees Fahrenheit (F), the curing process is slow; and below 40 degrees F, it essentially stops, and the concrete will not be as strong as it should. If the concrete freezes before it cures, its matrix can degrade. You must protect the curing concrete from cold weather as it cures for efficiency of time and cost.

Modular Fabric Structures for Winter Concreting and Cement Storage

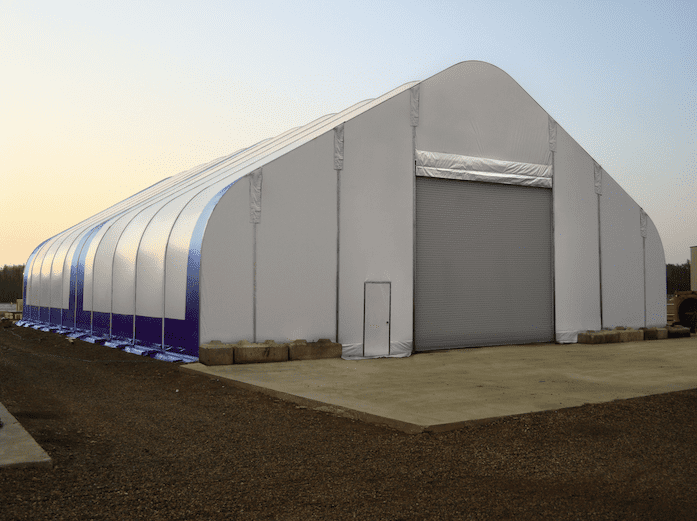

On-site storage facilities reduce logistical problems and transportation costs. Modular fabric buildings offer portable and reusable buildings with the versatility that the construction industry needs. Unlike traditional, permanent buildings, the modular design of fabric buildings can be quickly disassembled and reused at future construction sites, helping to reduce demolition and construction waste.

Custom-built storage facilities from Alaska Structures®️ protect from the wet and cold weather of winter. Our engineered fabric buildings maximize usable space with open span interiors of any width and designed to any side-wall height or overall building length. Our modular tension fabric buildings offer expansive interiors providing ample room between stacks for more efficient loading and unloading of inventory.

Engineered fabric buildings can protect concrete while it cures, for time efficiency and quality construction. With our versatile building solutions, you can customize the space to your cementing needs. We offer proprietary insulation packages up to any R-value, and our buildings can be outfitted with humidistat controllers, ventilation systems, and heaters to prevent issues associated with storing concrete or cold weather concreting.

The World’s Leading Provider of Engineered Fabric Structures

Alaska Structures has five decades of experience providing the most engineered fabric structures around the world. Since opening our doors, we have engineered, produced, shipped, and delivered more than 65,000 engineered and modular structures to remote locations with the most extreme climates, from the North Slope of Alaska with bone-chilling temperatures as low as -80 degrees F, to the searing deserts of Africa with +125 degree F temperatures, to the 17,500’ foot-elevation of Mount Everest’s base camp where avalanches and hurricane force winds occur frequently. No other fabric building manufacturer comes close to matching the volume or experience of Alaska Structures.

Alaska Structures has five decades of experience providing the most engineered fabric structures around the world. Since opening our doors, we have engineered, produced, shipped, and delivered more than 65,000 engineered and modular structures to remote locations with the most extreme climates, from the North Slope of Alaska with bone-chilling temperatures as low as -80 degrees F, to the searing deserts of Africa with +125 degree F temperatures, to the 17,500’ foot-elevation of Mount Everest’s base camp where avalanches and hurricane force winds occur frequently. No other fabric building manufacturer comes close to matching the volume or experience of Alaska Structures.

The Benefits of Engineered Fabric Buildings from Alaska Structures

There is a reason why project managers, concrete and cement business owners choose Alaska Structures. Aside from our unrivaled experience and manufacturing capabilities, engineered fabric buildings from Alaska Structures offer the following and many benefits:

- Custom built structures designed to your cement storage needs and building specification.

- Engineered to meet building codes for safety.

- Designed for quick and easy assembly. Our modular buildings do not require skilled contractors or expensive supervised crews.

- Unmatched ability to quickly take-down and relocate as your business needs change or to re-use for different construction projects.

- Minimal foundation requirements allow the cement storage facility or structure for cold weather concreting to be placed on virtually any level-surface, including: dirt, sand, gravel, asphalt, concrete slabs, footers or precast concrete blocks, or spanned between shipping containers.

- High-strength and galvanized steel or lightweight aluminum framing systems employ a free-span design allowing for maximum use of interior space. Optional powder coating is available for greater corrosion protection.

- Our proprietary and long-lasting fabric membrane systems offer a greater abrasion resistance, will not rot, are mold- and mildew-resistant, are UV stabilized (not coated) for prolonged exposure to high solar loads, and exceed fire safety standards outlined in the California Code of Regulations for membrane structures.

- Increase energy-efficiency, improve interior working conditions, or create an environment that is optimal for cold weather concreting with our large selection of proprietary insulation packages.

- Equip your cement storage facility or your modular structure for cold weather concreting with HVAC and air distribution systems. Alaska Structures produces the most ruggedized HVAC system available, called the Alaska ECU™ (environmental control unit). Keep your cement dry and at the optimal temperature with the following Alaska ECU™ models: 2.5-ton ECU, 5-ton ECU, and 10-ton ECU.

- Plug-and-play lighting and electrical systems available in 50 and 60 Hz eliminate the need for expensive electricians.*

- Our tensioned polyvinyl membranes are available in a wide assortment of colors and can be custom designed with different color combinations to blend in with existing infrastructure or stand out for safety. We also offer in-house printing services, allowing us to print your logo directly onto the fabric membrane for marketing and brand recognition.

- Translucent skylight material allows for the use of natural light to create a bright and safe work environment, while reducing energy usage and cost during the day.

- Choose from a large selection of equipment door, personnel door, and window options when designing a cement storage facility or cold weather concrete structure.

* A certified electrician may be required to connect the electrical distribution panel to shore power or local power utility. Please check with your local or state requirements.

Contact Us Today to Custom Design a Cement Storage Facility

Our knowledgeable building specialists can help you plan, design, and engineer the perfect cement storage facility to protect your inventory investment and increase efficiency.

For more information about how Alaska Structures can benefit your cement business or construction project, call us at +1-907-344-1565.

You can also email us or fill out our online contact form.

Leave a Reply