Long-Lasting Building Systems that Meet and Exceed Your Client’s Expectations

With so many options available, most building design and engineering firms overlook one of the best alternatives to traditional building designs — engineered tension fabric structures.

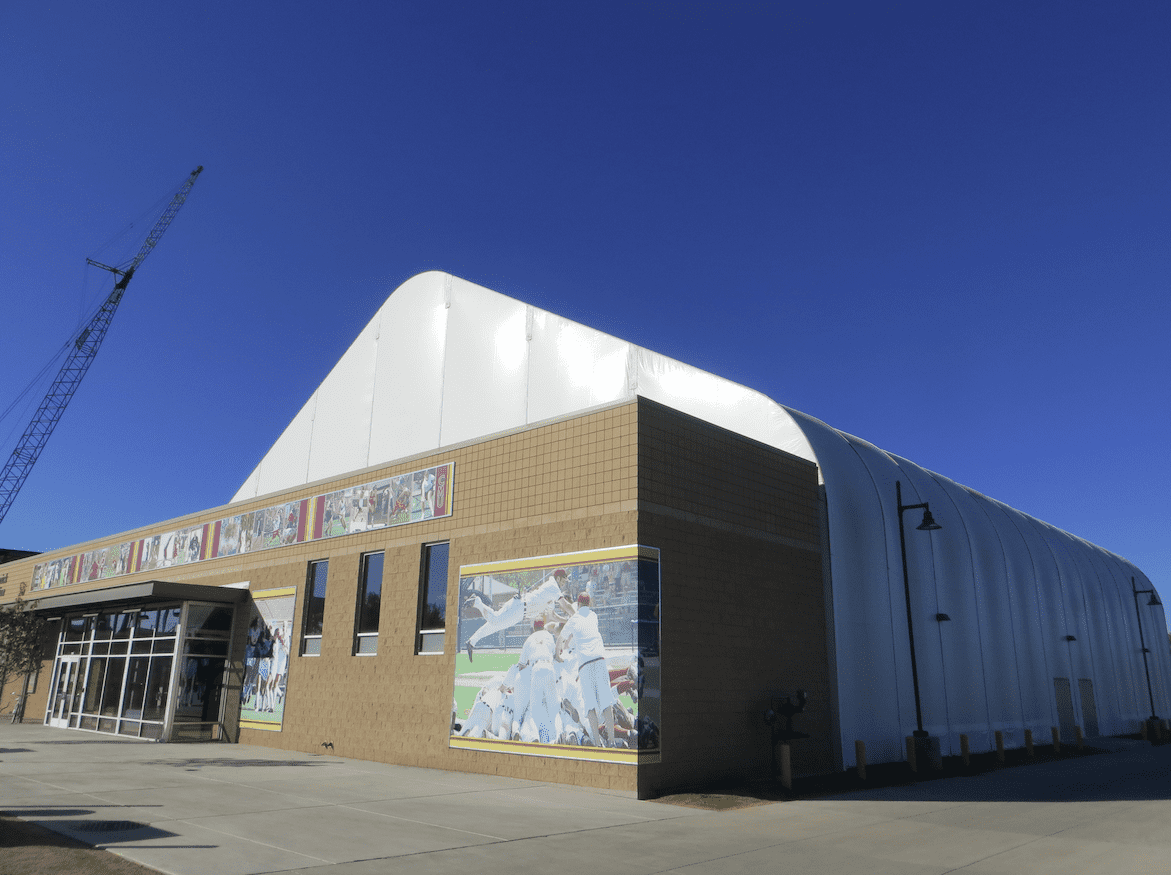

Alaska Structures® custom creates building solutions using high-performance membrane structures that offer unmatched engineering capabilities for residential and commercial building projects around the world. More than just a utilitarian building solution, engineered fabric buildings can be designed with the highest level of finishes, to create a high-performance building systems for the following applications:

- Modular office spaces

- Family entertainment centers

- Resort facilities

- Casinos

- Modular classrooms and school buildings

- Auditoriums

- Indoor sports facilities

- Aquatic centers

- Airport terminals, luggage and sorting facilities, and hangar facilities

- Worship centers

- Car dealership sales offices and show rooms

- On-site warehouses and distribution centers

- Workshops and vehicle repair facilities

The possibilities are nearly endless!

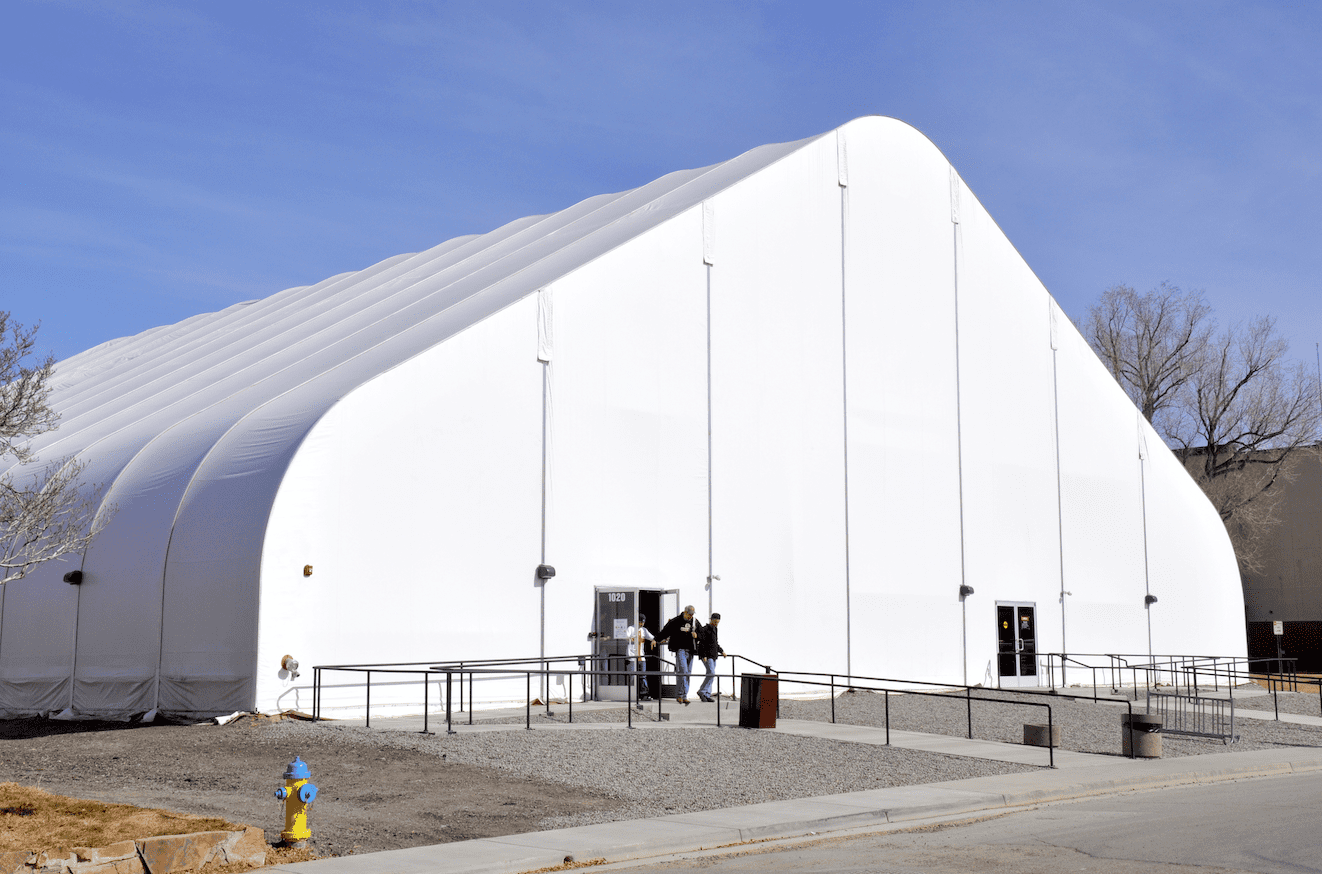

The free span design of engineered fabric buildings from Alaska Structures provide an unobstructed interior space and maximize use of interior floor space. More than just “tents” that provide temporary cover, fabric structures are an ideal building solution for short-term, semi-permanent, and even permanent applications.

One of the biggest misconceptions regarding the advantages of tension fabrics is that the fabric-covered structure isn’t durable and will not hold up to adverse weather conditions or prolonged use in extreme hot or cold climates. Innovations in material technology and manufacturing capabilities have resulted in tensioned polyvinyl membranes that are engineered to meet the demands of all climates and endure decades of use.

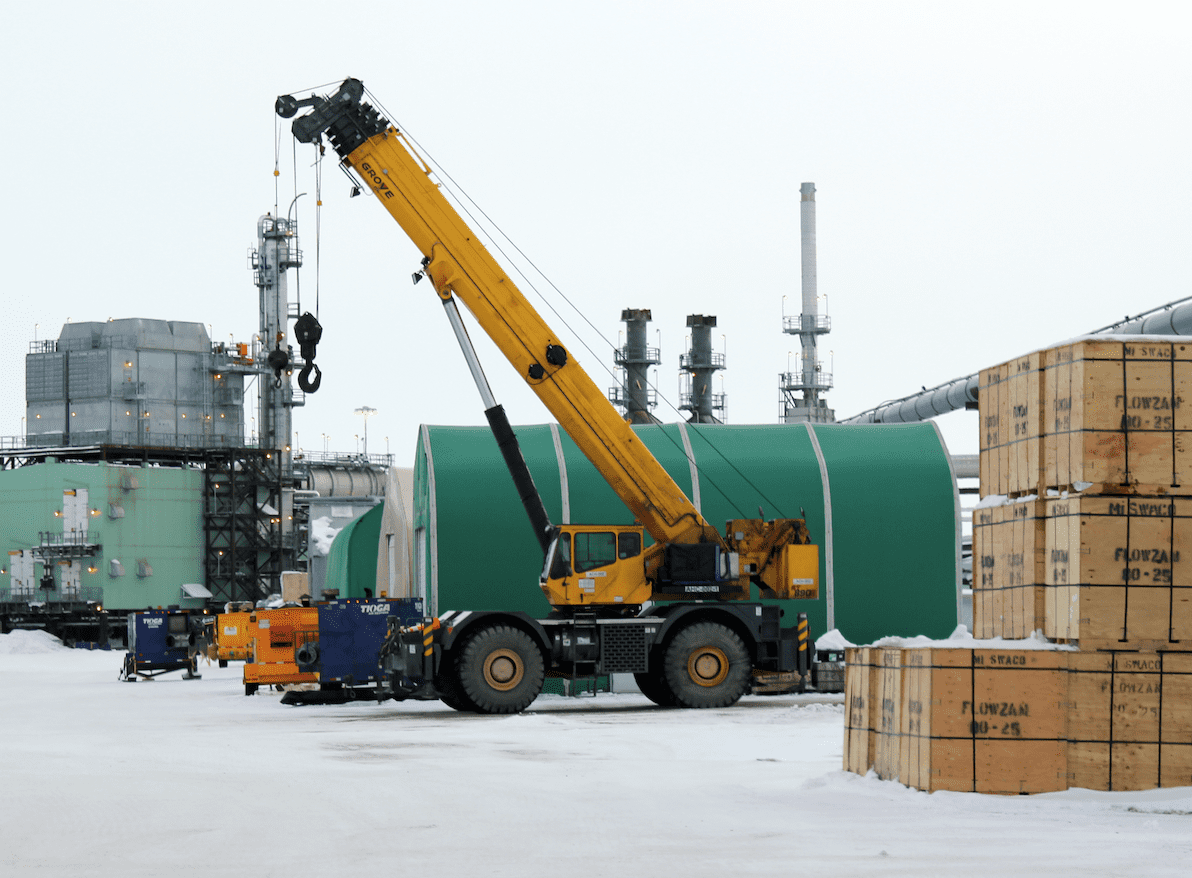

In the mid-‘70s, Alaska Structures was the first company to successfully develop fabric structures that were engineered to meet building codes and withstand the harsh Alaskan North Slope environment. With an annual snowfall of 46.2 inches, temperatures consistently below freezing, and wind gusts up to 90 mph, buildings need to be engineered and specifically designed to meet the demanding environmental conditions. While others failed to withstand the high winds and heavy snow loads, only Alaska Structures building systems proved capable of facing the functional and environmental challenges of the North Slope.

Since opening our doors and engineering fabric structures to withstand the Arctic conditions of the North Slope of Alaska, our dedicated team of in-house engineers have continued to push the envelope of material and manufacturing technology to create modular structures capable of meeting extreme and global conditions, including dry desert heat, humid tropical environments, coastal environments with corrosive sea spray, and high altitude locations with extreme wind and UV exposure. With over 65,000 engineered fabric buildings designed, produced, and delivered on time and within budget, no other building manufacture comes close to matching our level of expertise!

Benefits of Engineered Fabric Buildings from Alaska Structures

Alaska Structures works with clients, engineers, architects, developers, building owners, and consultants through all phases of the project, starting with the creative conception of the design. During this stage, Alaska Structures works closely with engineering firms and architects to plan the building design, including any temporary structures for storage and other facilities needed during construction.

Unlike suppliers that create a handful of pre-fabricated structures, Alaska Structures creates custom-built structures designed to meet our customer’s specific building requirement. This allows firms to create the perfect building design – meeting both practical and aesthetic purposes.

Engineered fabric structures from Alaska Structures can be designed up to any width, with any side-wall height, and specified to any length! Choose from a large selection of doors and windows, as well as proprietary energy-saving insulation and HVAC systems to increase energy-efficiency and comfort. Plug-and-play lighting and electrical systems are designed for easy installation and are available in 50 Hz or 60 Hz configurations.

Engineered fabric structures from Alaska Structures can be designed up to any width, with any side-wall height, and specified to any length! Choose from a large selection of doors and windows, as well as proprietary energy-saving insulation and HVAC systems to increase energy-efficiency and comfort. Plug-and-play lighting and electrical systems are designed for easy installation and are available in 50 Hz or 60 Hz configurations.

The color of the fabrics can also be customized, either from one of our preset styles or with a design of your own. Our in-house printing services allow us to print directly onto the tensioned fabric membranes to create building systems that advertise your company name, products or services, as well as assist with brand recognition.

Unlike other building systems, building solutions from Alaska Structures do not require expensive supervisors or setup crews. This allows companies to use in-house labor or hire local non-skilled labor for construction. Our advanced level of engineering, unmatched expertise, and building design allow our structures to be easily assembled in a fraction of the time.

The result is an entirely custom-built structure that fits your client’s unique building needs.

Engineered Fabric Structures Compared to Conventional Construction

As opposed to brick and mortar, wood-built structures, and steel buildings, engineered fabric buildings from Alaska Structures reduce overall construction costs.

Benefits of Engineered Fabric Structures from Alaska Structures:

- Minimal foundation and site preparation requirements

- Minimal tool, equipment, and labor requirements (no crews or supervisors necessary)

- Fast setups of permanent and temporary building systems, allowing for shorter construction times

- The option of semi-permanent, temporary, and module building systems that can be left in place or relocated with ease

- Low-maintenance building systems, as our engineered fabric membranes:

- Will not rot

- Are mold- and mildew-resistant

- Offer greater abrasion resistance than other polyethylene- and polyvinyl-based fabrics

- Are UV-stabilized (not coated) for prolonged and year-round use in locations with high solar loads

- Are chemically inert

- Exceed the fire safety requirements outlined in the California Code of Regulations for membrane structures

- A free span design that allows for large, open interior spaces with no obstructions

- Custom engineering that meets both local and international building and safety codes

Contact Us Today to Discuss Your Upcoming Building Design Project

Alaska Structures has designed, engineered, and delivered more temporary and permanent fabric structures than any other prefabricated building company, to more than 70 different countries. Rely on our proven experience and expertise to provide the longest-lasting and engineered fabric building systems available!

Send Inquiries for Engineered Fabric Building to:

Get started by calling us at +1-907-344-1565, emailing us, or using our online contact form to submit an inquiry!

Leave a Reply