Mine Tailings Explained

After miners extract a valuable fraction of minerals or oil from the material that surrounds it, the economically worthless leftovers contain a slurry of fine particles and water, known as tailings. Oil sands mining and placer mining of minerals and metals both use water and gravity to extract the mined product, and the result is called a tailings pond. Hardrock mining for harder minerals uses chemical reactions, in addition to water, to separate the ore from the surrounding material.

Separating the desired solids from the slurry requires large volumes of water and gravity, leaving coarse and fine sand behind in the water — the tailings stream. The tailings settle out during storage in the ponds, and the clarified supernatant can be reclaimed and used for further processing of ore. These ponds are large enough to hold the tailings until settling occurs and to prevent heavy precipitation from exceeding the pond’s capacity. Frequent pumping out of the water prevents overflow.

The solids that accumulate are a mixture of fine and coarse particles, and the fine fluid tailings will become mature fine tailings (MFT) if unprocessed. MFT traps water in such a way that makes it difficult to remove, taking decades to settle out.

A critical component of mining is water management and the end goal is to reduce usage of water. Mine operators are allowed a certain amount of local water usage, and risk shut down of operations after exceeding that. Having a sufficient volume of recyclable water is crucial to prevent shutdowns. Using recycled water from the ponds helps to maintain adequate water, but another critical conservation tactic is the prevention of pond evaporation.

Given the large volumes of water that are required, the ponds must conserve as much water as possible, so the enclosures must last for years and, depending on where the mine is located, withstand severe weather. Different types of mining operations have different substances present in their tailings ponds, but they are always toxic and often corrosive.

Environmental Risks of Mining

Mining has significant environmental risks. Some of the toxic compounds commonly found in tailings ponds include:

- Heavy metals

- Naphthenic acids

- Polycyclic aromatic hydrocarbons

- Phenolic compounds

- Ammonia

These ponds can become damaged and their contents can be released into the local environment with disastrous effects, such as what happened at the Mount Polley copper and gold mine in British Columbia, Canada. Tailings ponds can leak slowly and contaminate groundwater, which provides drinking water, helps grow crops, and replenishes lakes, rivers, and watersheds. Wildlife can come into direct contact with mining tailings, as happened in a Canadian mine in 2012.

Tailings Pond Enclosures

Tailings pond enclosures help reduce environmental impacts, such as:

- Wind blowing hazardous chemicals into populated areas or across environmentally sensitive landscapes

- Large amounts of rain from quickly filling tailings ponds, resulting in overflow or spillage

- Open-air tailings ponds suffering from evaporation, creating the need to replenish more water – typically from a local source

- Wildlife coming into direct contact with toxic tailings

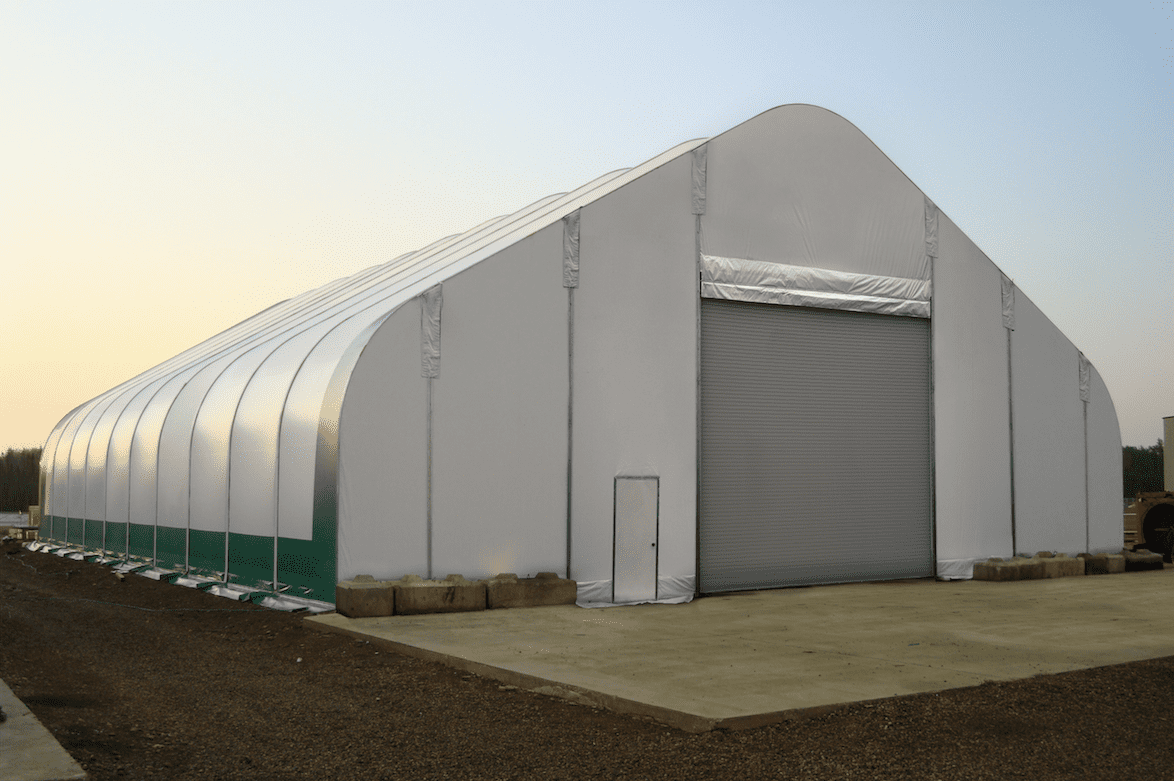

Engineered fabric buildings from Alaska Structures®️ are custom-build structures, designed to meet your specific tailings pond enclosure needs. Our tension fabric buildings provide an instant structure solution to meet the needs of mining operators who must work to prevent tailings ponds from contaminating the surrounding area or the local groundwater.

Fabric Buildings Designed for Longevity

Mines operate in environments that range from frigid Saskatchewan uranium mines in northern Canada to open-pit copper mines in the Sonoran Desert. The operations of a mine can last from a few years to decades, after which mining operators are required to return the mining site to a state that will not pose an environmental or societal effect. Reclamation efforts can take years after mining operations have ceased. Alaska Structures uses high-strength architectural membranes that are UV stabilized for years of prolonged exposure to high solar loads and engineered to withstand temperatures from -80 degrees F to +130 degrees F.

Instant Structures with Minimal Foundation Requirements

Tailings ponds are often in environments where ground conditions make it difficult (and expensive) to construct a typical foundation, such as the Athabasca oil sands in Alberta, Canada, which lie under peat bogs. Alaska Structures fabric buildings have minimal foundation requirements that allow reduced environmental disruption and safe anchoring on nearly any level surface including:

- Dirt

- Gravel

- Sand

- Asphalt or concrete

- Concrete slabs, footers, or pilings

- Wood platforms

- Ecology blocks (precast concrete blocks)

- Spanned between shipping containers

Rugged Construction and Custom Sizing for Tailings Pond Enclosures

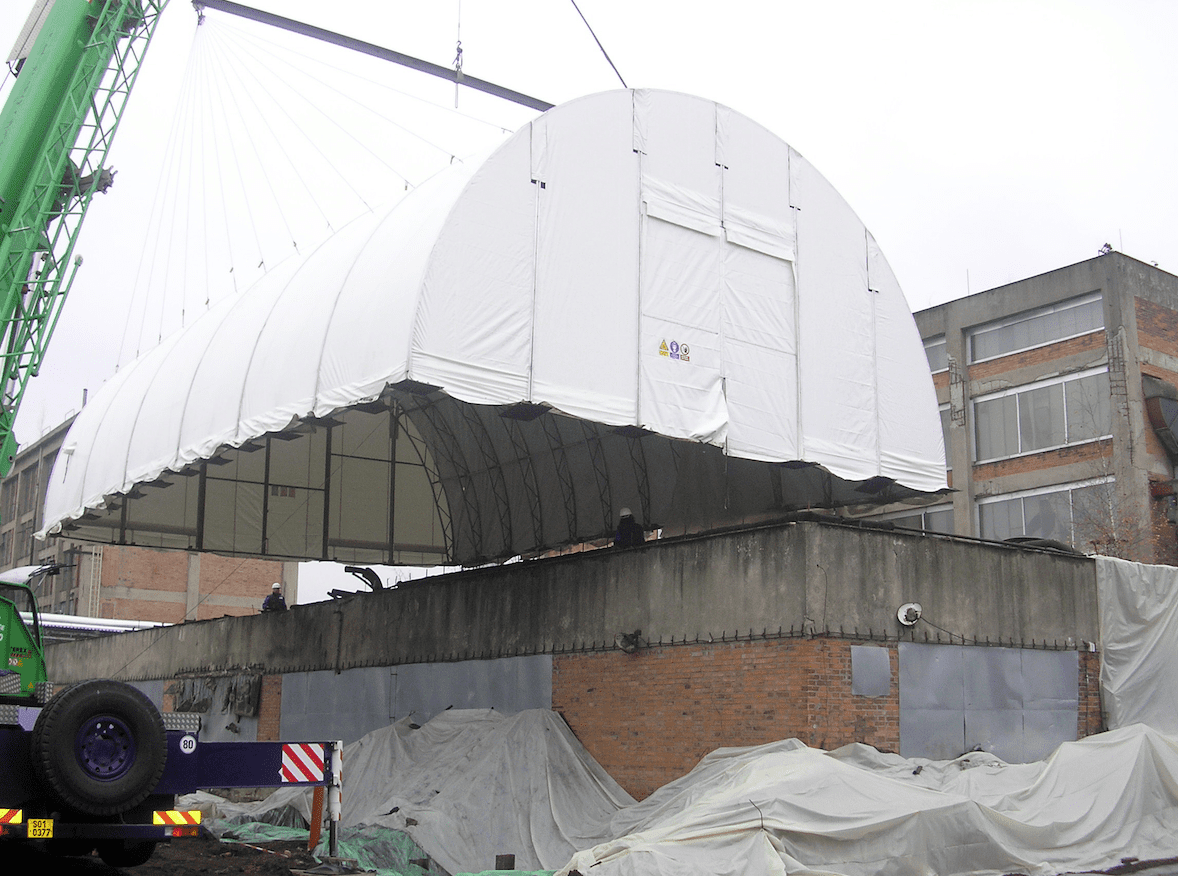

Alaska Structures offers both lightweight aluminum and high-strength galvanized steel frame systems. Optional powder coating is available as an added level of protection from salt air, oxidation, humidity, and corrosive tailings ponds. We provide crane-liftable buildings to allow placement over existing ponds.

Our open span building design provides an unobstructed interior, and because tailings ponds come in all different shapes and sizes, Alaska Structures will work with mining, oil and gas, and environmental remediation organizations to develop custom-built tailings storage facilities to meet their specifications.

Modular Buildings for Workforce Accommodations

Mining operations and the following reclamations involve crews of people that may require accommodations, especially in remote locations or areas with extreme weather that makes traveling long distances to reach the mine site treacherous.

Alaska Structures can meet the housing and accommodation needs of mining crews from 10 to 5,000 people. We offer a wide selection of building models, sizes, and styles. All of which can be custom configured to meet your specific workforce housing requirements and to comply with local or governing rules and regulations.

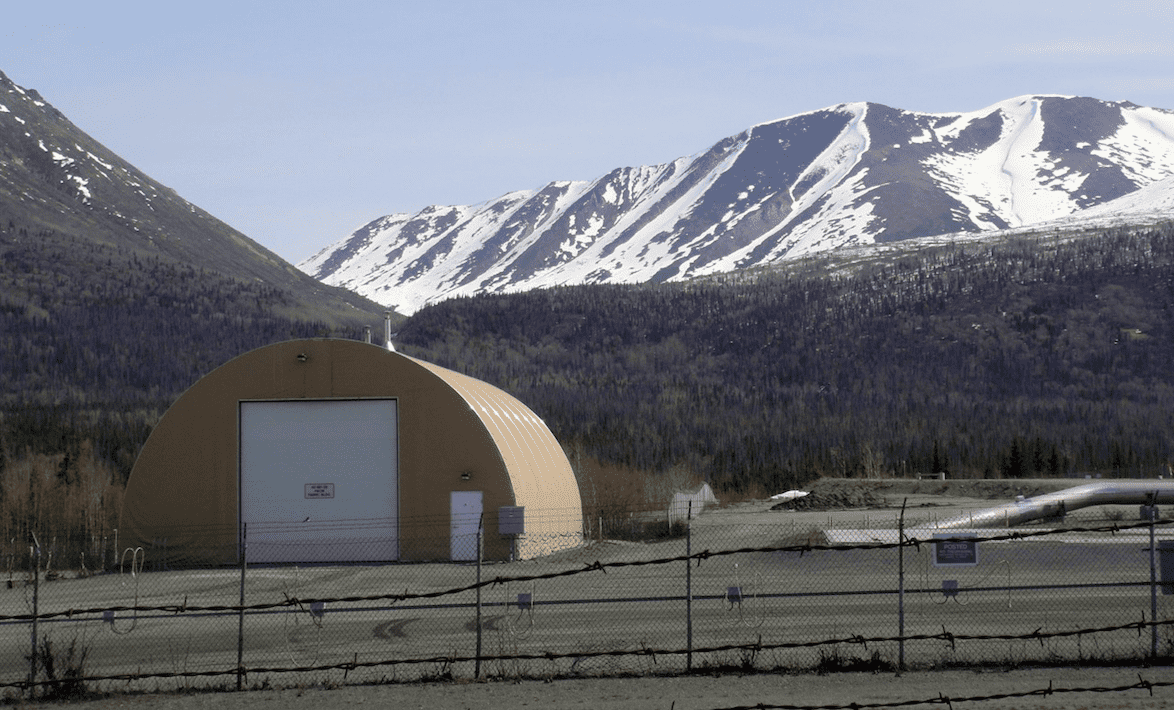

Available in widths up to 30-feet wide, and custom designed to any length – our versatile SQ Series are a modern building system that gets it’s looks from the quonset hut style, and can be configured to provide workforce housing accommodations for workers, managers, and supervisors.

Mining Buildings and Enclosures for All Mining Operations

Alaska Structures produces modular buildings and camp systems to support all activities of mining operations. Our engineered fabric structures are designed to stand up to the world’s harshest environments and meet current local and international building codes for safety and durability.

In addition to custom-built structures for mining ponds, reclamation structures, and tailings pond enclosures, you can use engineered fabric structures from Alaska Structures to house and protect sensitive monitoring and testing equipment, pump stations, and material handling equipment, and as bulk storage facilities for preprocessed ore.

Our experienced building specialist will work with mining, oil and gas, and environmental remediation companies to develop custom-built structures, designed to meet your exact building specifications and engineered to provide an unmatched level of durability.

If you would like to discuss using an engineered fabric building for your mining or reclamation site, please:

- Call us at +1-907-344-1565.

- Email us

- Chat with one of our building specialists.

Contact us online.

Leave a Reply