The timber industry has taken a hit in the last couple of decades. Fewer young people are lining up to fill job vacancies partly because it is one of the most dangerous professions and its hard work. The Bureau of Labor reports that in 2015, logging workers suffered the highest rate of fatal injuries in the U.S., with more than 132 fatal injuries per 100,000 people. When combined, the risk of injury, low wages, and lack of training programs result in the current labor shortage in the timber industry.

Despite the labor shortage, spending in the lumber-dependent construction industry rose in 2018, and experts predict that this trend will continue. In addition to housing and paper products, wood pulp is also used to produce biodiesel, and research shows that wood fibers can produce many traditionally fossil fuel-derived products. The bottom line is that wood and wood products are still very much in demand.

Technology has enabled timber companies to keep up with market demand, producing an increasing volume of wood products with far fewer workers. Machinery such as forwarders, yarding machines, and harvesters perform the work that, in the past, entailed manual rigging by an entire crew.

The U.S. timber industry is a commodities industry and, as such, has a lot of market highs and lows, depending on the value of the dollar. Industries such as this generally have large equipment expenditures and low profit margins. Efficiency is crucial for the financial health of logging companies.

The Benefits of Fabric Structures for the Timber Industry

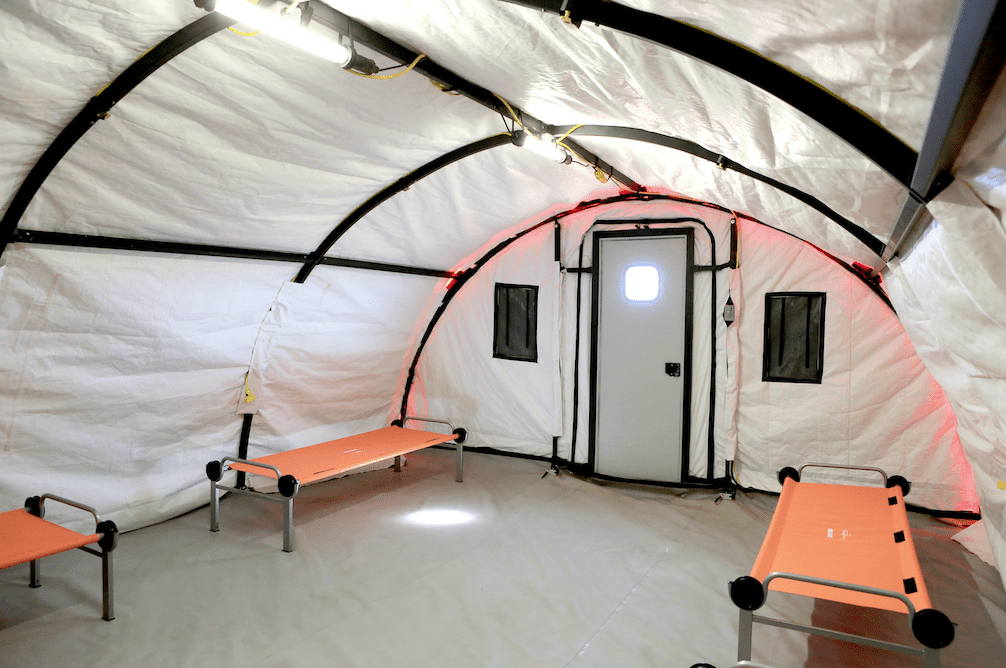

Engineered fabric buildings can help logging companies protect their sizeable machinery investment, provide comfortable lodging for work crews working in remote areas, or quickly establish infrastructure needed for logging ports and hubs for the movement of local and non-local forest products being sold to domestic and international markets.

Engineered fabric buildings can help logging companies protect their sizeable machinery investment, provide comfortable lodging for work crews working in remote areas, or quickly establish infrastructure needed for logging ports and hubs for the movement of local and non-local forest products being sold to domestic and international markets.

Compared to traditional construction or modular trailers, engineered fabric structures offer many advantages including much faster assembly times and the ability to easily relocate. Logging companies that are subject to the whims of the market can benefit from the efficiency of tension thermoplastic membrane buildings.

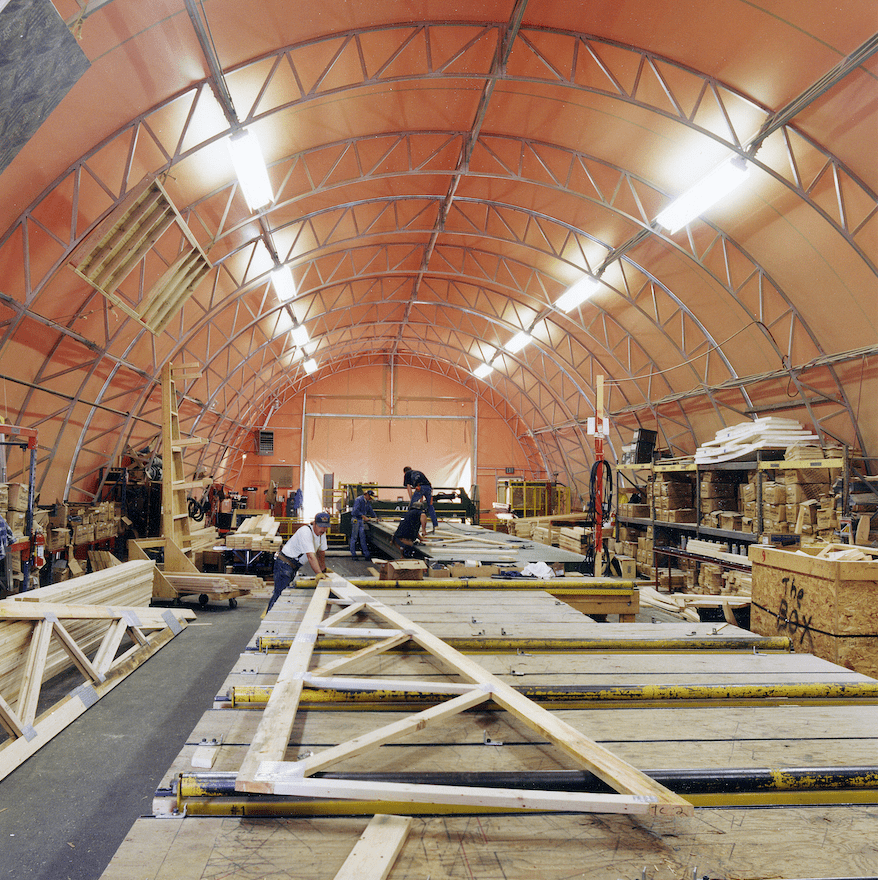

Temporary or permanent building solutions, like tensioned membrane structures, are used to assist with on-site processing, cutting, skidding, or loading of trees or logs onto trucks, or port facilities for banding, decking, round booming, rafting, roll-out scaling and sorting, reloading, de-watering inbound cargo, or container loading.

Modular Structures Engineered for Durability

Alaska Structures® engineers modular structures that are custom designed to support all aspects of the timber industry, including modular housing and workforce accommodations in remote locations, on-site storage and processing facilities, modular offices, and maintenance buildings. All of our thermoplastic fabric buildings are engineered to meet location specific wind and snow loads as required by building codes for safety.

Logging is traditionally done in winter months when the frozen ground or snow cover prevents erosion of the site. If not properly maintained, heavy equipment can suffer in cold weather, and not perform as efficiently. Companies can protect their costly equipment by providing a dry, warm space for storage and maintenance. Non-engineered structures used in these cold climates can not only risk damaging expensive logging equipment, but also put the lives of crews at further risk of injury or death.

The labor shortage in the timber industry is due, in part, to the physical nature of the job. Companies need to provide as much comfort to their employees as possible to attract and maintain a skilled workforce. Modular buildings and remote work camps from Alaska Structures are custom designed and have been providing a home-away-from-home since 1975.

Alaska Structures is the leading provider of engineered fabric structures and workforce camps, with more than 65,000 buildings successfully engineered, produced, delivered on time and within budget, and used in more than 85 countries around the world.

Engineered Fabric Structures with Minimal Foundation Requirements

Engineered fabric structures from Alaska Structures can be securely anchored to virtually any level surface, including:

- Precast slab sections

- Precast concrete blocks

- Sub-grade continuous and pier footers

- Gravel and earth pads

- Sand

- Wood platforms

The minimal foundation requirements allow crews to quickly and efficiently install on-site storage and maintenance facilities. Preparation of the site is much less involved and time-consuming than other modular structures. Temporary foundations require less skilled labor, both for set up and disassembly.

Sustainable logging considers the environmental impact of their operations, and companies strive to reduce impact. Preventing damage to the surrounding forest is a technique that minimizes erosion and waste. Without the need to dig foundations, engineered fabric structures can be used temporarily and have less impact on the forest ecosystem than traditionally constructed buildings.

Engineered Fabric Buildings with High-Strength Frame Systems

The high-strength frame systems employed in thermoplastic fabric buildings from Alaska Structures® are engineered for longevity and durability. With the ability to design and engineer logging facilities up to any width, side-wall height and length, an Alaska Structures® can meet any building requirement for log yards, port facilities, or on-site logging operations.

Depending on the building size needed and the engineering required for your logging project, we offer building systems in lightweight aluminum or high-strength galvanized steel framing systems. Both are highly portable and offer robust strength, even in the most challenging of conditions.

Optional powder coating offers a greater degree of corrosion protection against the elements, especially in environments with sea spray, salt, high humidity, or when storing corrosive materials.

Long-Lasting Engineered Fabric Membranes

Alaska Structures engineers the longest-lasting tensioned fabric membranes available. Our proprietary blend of materials has been perfected over five decades of engineering building systems capable of enduring prolonged exposure in the harshest weather conditions and in some of the most extreme locations in the world.

Our tensioned fabric membranes offer a greater abrasion resistance than other materials, will not rot, are resistant to mold and mildew, and are UV-stabilized to withstand prolonged exposure to high solar loads, and exceed the fire safety ratings outlined in the California Code of Regulations for membrane structures.

Fabric Buildings Provide Many Cost-Saving Solutions for the Timber Industry

Engineered fabric buildings from Alaska Structures provide many cost-saving benefits for the timber industry, including:

Engineered fabric buildings from Alaska Structures provide many cost-saving benefits for the timber industry, including:

- Minimal foundation requirement allows for the safe installation of workforce housing, storage facilities, warehouses, and maintenance buildings onto virtually any level surface, reducing the need for expensive and time-consuming preconstruction site work.

- General laborers can assemble our buildings – expensive setup crews, trained contractors, or supervisors are not required.

- Considerably shorter construction timelines allow you to start your logging operation more quickly, without costly delays.

- Translucent skylight material allows for the utilization of natural light during the day and creates a bright and safe working environment while reducing energy usage and costs.

- Plug-and-play lighting and electrical systems, available in 50 Hz and 60 Hz, eliminate the need for expensive electricians.¹

- Optional insulation packages capable of meeting any R-value provide a higher level of comfort and help reduce heating and cooling costs.

- Buildings can be easily expanded, reconfigured, or relocated to future logging sites, preventing the need for further construction.

¹ A certified electrician may be required to connect the electrical distribution panel to shore power or local power utility. Please check with your local or state requirements.

Contact Us Today to Discuss Your Logging Facility Needs

Reusable, modular, and engineered fabric buildings from Alaska Structures provide a greater efficiency and a better return on investment – saving your logging operation both time and money. Rely on our 50 years of proven experience custom designing and engineering building systems to support all aspects of the logging and timber industry by calling us today at +1-907-344-1565 or email us.

Or use our online contact form that to submit an inquiry and get started on your logging facility project.

Leave a Reply