At Alaska Structures®, we believe our technology and engineering set us apart from other fabric structure companies. We engineer all our fabric buildings and remote camp systems to meet area-specific wind and snow loads, as local codes or the International Building Code (IBC) requires. Additionally, we design our optional lighting and electrical systems to meet the temporary section of the National Electric Code (NEC) for safety.

Our modular fabric buildings offer a large degree of versatility and durability. We manufacture them with the highest-quality materials to outlast and outperform other non-engineered building systems. Learn more about our industry-leading engineered fabric buildings today. Call us at +1-907-344-1565 or complete our online contact form.

The Longest-Lasting Tensioned Fabric Membranes

Fabric buildings from Alaska Structures feature tensioned membranes that offer an unmatched level of durability. Compared to the PE- or PVC-based fabric products that other companies use, our fabric membranes offer these benefits:

- Greater abrasion resistance

- Rot resistance

- Mold and mildew resistance

- UV stabilization for prolonged exposure to high solar loads

- Engineering to withstand extreme hot and cold temperatures

- Chemically inert features

Alaska Structures also offers fabric membranes that we specifically design to exceed the fire safety requirements in the California Code of Regulations for membrane structures.

Fabric Buildings with Minimal Foundation Requirements

We design our engineered fabric buildings for secure anchoring on virtually any level surface. Minimal foundation requirements help our clients quickly establish on-site warehousing or workforce housing with less site preparation than other prefabricated building systems. In fact, clients can securely anchor all our fabric buildings to the following:

- Poured-in-Place (Pip) Concrete Walls

- Concrete Slab-on-Grade

- Precast Slab Sections

- Precast Concrete Blocks

- Sub-Grade Continuous and Pier Footers

- Asphalt

- Gravel or Earth Pads

- Sand

- Wood Platforms

- Shipping Containers

Please visit our Foundation Options for Fabric Buildings page for additional anchoring information.

High-Strength Frame Systems

At Alaska Structures, we engineer our metal frame systems to meet any challenge. Our lightweight aluminum frames perfectly suit highly portable applications, such as quick-erect shelters for modular housing, mobile offices, field kitchens and storage facilities.

Our high-strength galvanized steel frames are ideal for large fabric buildings that create instant structures for on-site warehousing, aircraft hangars and manufacturing space. They also easily accommodate dining facilities for large mining, oil and gas and construction camps.

Additionally, Alaska Structures offers two frame types based on the building size and your area’s specific wind and snow loads.

Structure Sizes and Uses

Clients generally use single-arch buildings for applications needing a small building solution up to 30 feet wide, such as the following:

- One- or two-person sleeper shelters

- Modular housing for workforce camps

- Core storage facilities

- On-site laboratories and research facilities for remote projects

Our large fabric buildings are configurable to any sizes and employ a high-strength double-truss design. They employ a high-strength truss design. Our large fabric buildings are a robust building solution for quickly creating expansive structures:

- Mission-critical buildings

- Rapid manufacturing facilities

- Workshops

- On-site warehouses

- Maintenance facilities

Alaska Structures has an in-house powder coating facility that improves product quality and longevity. Powder coating provides an added level of protection from rust, salt air, oxidation, humidity and other environmental factors. We recommend it for fabric buildings in coastal areas or anywhere sea-spray occurs.

Additionally, we offer powder-coated frame systems in tan or gray standard colors. Specialty colors (black, white, red, and blue) may be available upon request, at an additional cost. Contact us for more information.

Secure Anchoring Systems

Alaska Structures offers many high-strength, field-tested anchoring options that adhere to rigorous safety standards. Our double-headed ground spikes and duckbill anchors are popular options for anchoring directly into the ground. Clients use lag bolts to quickly and easily attach any of our modular building solutions to wood foundations or platforms. We also offer concrete anchors in various sizes.

If your project requires tensioned fabric structures anchored to shipping containers, skids or trailers, you can easily bolt or weld our structures’ high-strength frames to the supporting structure. We’ve also created a rail-based rolling system for increased mobility using our DAGB Series™ gable truss buildings.

Please visit our Foundation Options for Fabric Buildings page for more information about our anchoring solutions.

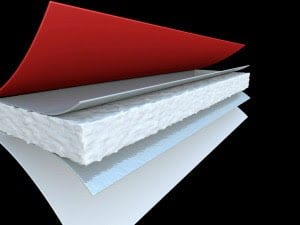

Energy-Efficient Insulation Systems

Alaska Structures designs and produces proprietary insulation systems available for all our high-quality fabric structures. Our integrated product approach allows us to create insulated fabric buildings. Our buildings are energy efficient, highly portable, pack small for low-cube shipping and are easy to install, no matter your skill level.

Plug-and-Play Electrical Systems

Our electrical systems feature “plug-and-play” designs to reduce the time and energy required for setup. We also prebuild our electrical systems before shipping, which allows general laborers to install them on-site. Depending on your area’s construction rules, you may need skilled electricians only when connecting the electrical system to a power source. We build our electrical systems using materials and components that meet National Electrical Code standards, per NEC Article 590. Furthermore, we can configure our electrical systems for U.S. or European power.