Fabric Buildings Designed for Safety and Durability

Whether you’re choosing among fabric structures or comparing fabric structures to conventional buildings, our engineered fabric buildings provide an array of advantages.

Safety and Durability

Alaska Structures ensures the safety and durability of your fabric structures with these benefits:

- Field- and laboratory-tested for unmatched durability and longevity

- Engineered to meet local codes, the International Building Code (IBC) and the National Electrical Code (NEC) safety standards

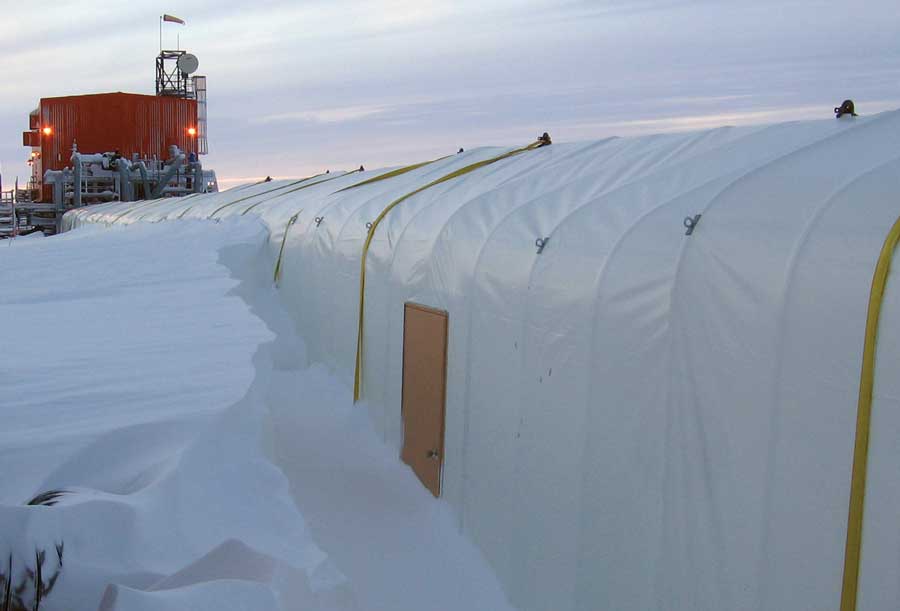

- Weatherproof enclosures that protect personnel, equipment and vehicles during extreme weather

- Frame systems made of high-strength galvanized steel or aircraft-grade aluminum and treated for corrosion resistance

- Virtually maintenance-free

- Tensioned fabric membranes that provide these advantages:

- Abrasion resistance

- UV stabilization for prolonged high solar load exposure

- Rot resistance

- Mold and mildew resistance

Additionally, powder-coated frames are available. These frames increase corrosion resistance against rust, oxidation, humidity, sea spray and corrosive materials storage.

When clients use our fabric buildings as either temporary structures or permanent facilities, our structures withstand high winds, heavy snow loads and other extreme conditions. Unlike companies that rely on a “snow shed” to reduce engineering, our fabric buildings meet specific snow loads for durability, as local codes or the International Building Code (IBC) requires.

High-Quality Engineering

At Alaska Structures, we take engineering and our fabric buildings’ safety very seriously. That’s why we rely on a unique, multipronged engineering approach.

First, our in-house engineers consider concrete information to design a fabric building that meets our client’s specific requirements:

- Site location

- Environment

- Wind and snow loads

- Building use and occupancy

- Latest local codes

- The International Building Code (IBC) standards

Then, they use this information to create a detailed 3D model. Our engineers use this 3D model to perform a nonlinear analysis regarding the AISC 13 steel code and design guide specifications. Additionally, they use finite element analysis studies to determine our fabric structures’ specific responses and behaviors.

Overall, this engineering process is far superior at predicting loads and stresses for actual points on the structure. Because of the time and cost that come with generating detailed 3D models, no other fabric building provider offers this level of engineering.

Easy Transportation, Installation and Relocation

Design That Benefits You

We specifically design our structures to provide additional benefits:

- Lower logistic and transportation costs

- Fast installation

- Quick takedown and relocation

First, low-cube packaging allows us to deliver your fabric structures anywhere in the world quickly and cost-effectively. With 50-plus years of proven experience, our logistics team has built amazing relationships with global shipping and freight companies. As a result, we ensure the safe and timely arrival of your fabric buildings and systems.

Next, your crews can quickly assemble our structures with little site preparation, skill and equipment. Conventional building methods often take months or even years to complete. However, our instant structures, depending on their size and configuration, can be fully operational in less than one week.

Furthermore, clients can set up our expeditionary shelter systems in as little as 30 minutes, depending on the structure’s size and scope. Plus, shorter construction times mean lower construction costs.

In fact, clients can install most of our buildings without our help. Still, we offer experienced supervisors to work with hired local labor. Alternatively, we can send complete setup crews to guarantee your project is functional on time and per budget.

When you need to relocate your project, you can quickly dismantle, package and ship our fabric structures to the next location. This ensures your building needs don’t halt or delay operations.

Multipurpose Fabric Buildings

Engineering for Smooth Operations

Fabric buildings from Alaska Structures come in many models and sizes, which makes them incredibly versatile and ideal for nearly any application or industry.

Moreover, we don’t merely engineer them for decades of use in extreme environments with high winds and heavy snow loads. Our structures are also effective for both common and unique commercial and industrial uses. Here are a few examples:

- Mission-critical buildings

- Storage and warehousing

- Vehicle maintenance facilities

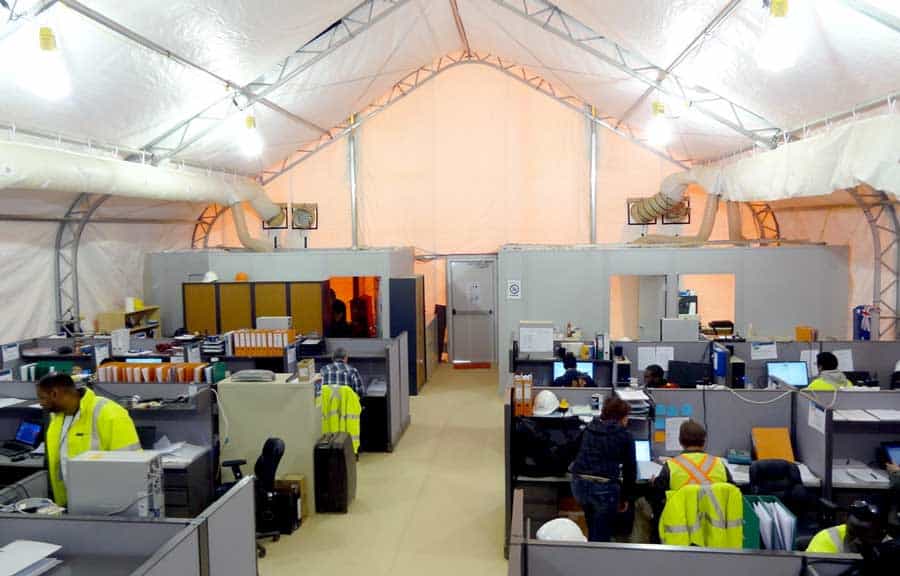

- Modular office buildings

- Modular buildings for workforce housing and camp systems

- Arctic exploration and research facilities

- Airplane hangars

Our structures’ open-span design means you need no internal posts, pillars, columns or beams. Plus, our fabric building interiors’ expansive design and high ceilings maximize both floorspace and usable space. Our buildings have plenty of clearance for equipment or machinery storage (e.g., a helicopter, crushing equipment), in addition to stacking space if the building is for warehousing.

To meet your specific requirements, you have the following options available to configure our fabric buildings:

- Building models and sizes

- Window and door packages

- Insulation and liner systems

- HVAC

- Plug-and-play lighting and electrical systems

- Modular flooring and anchoring packages

- Fabric colors, patterns and/or printed logos

Increased Energy Efficiency and Sustainability

We can configure our high-performance fabric buildings to offer many energy-saving benefits, including the following:

- Translucent fabrics and skylights that allow in natural light, reducing power needed to illuminate interiors during daytime

- LED lighting systems that create bright and safe working environments and reduce energy use

- Optional insulation packages that meet any R-value and lower the heating or cooling needed to maintain comfortable working and living spaces

In fact, Alaska Structures uses materials that are more environmentally sustainable than those other manufacturers use to construct traditional buildings. We use lean manufacturing methods to reduce waste and recycle scrap materials.

Proven Expertise

Alaska Structures has designed, produced, delivered and installed more than 29,000 engineered fabric structures in 85-plus countries.

Furthermore, clients have used our tensioned fabric buildings for decades in extreme locations. These include the base camp of Mt. Everest (17,500-ft. elevation), the North Slope of Alaska, the ice shelf of Antarctica, the jungles of South America and the deserts of Africa.

No other fabric building provider comes close to matching our technical expertise and proven experience.