Marketplace competition continues to push the boundaries, demanding more efficient services. In industries that use heavy machinery, this is even more important because crews often depend on heavy machinery to be able to work at all. Minimizing loss accrued from this means minimizing downtime by taking control of as many variables as possible.

How Weather Can Negatively Impact Heavy Equipment

Sun, rain, snow, and wind can all dramatically impact your equipment for the worse.

Cold weather wreaks havoc on your equipment. It thickens the fluids needed for hydraulic systems, engines, breaks, radiators, and transmissions to work properly. For every 10 degrees Fahrenheit the temperature drops, tire pressure in vehicles drops by 1 pound per square inch (psi). Lastly, the cold drains the voltage in batteries, making it more difficult to start equipment.

Heat can be just as bad on equipment, especially dry heat. Higher temperatures dry-rot rubber components such as tires, drain power from batteries, and places additional heat stress on all mechanical components.

Minimize Heavy Equipment Downtime

When heavy machinery breaks down, options are limited. You have to buy new parts, ship them, and repair your equipment either onsite or at a heavy equipment repair shop. Alternatively, you could replace the equipment altogether, but this would be at a significant long-term financial loss, giving you a miserable life-to-date cost.

Beyond the cost of repairing the equipment, every second that your crew is unable to work because the necessary machinery is not functioning is time lost and money burnt. This changes downtime from a single cost schedule dilemma to a perpetual slow burn of your profit.

Minimize downtime by taking control of as many variables as possible.

Engineered Fabric Structures for Heavy Equipment

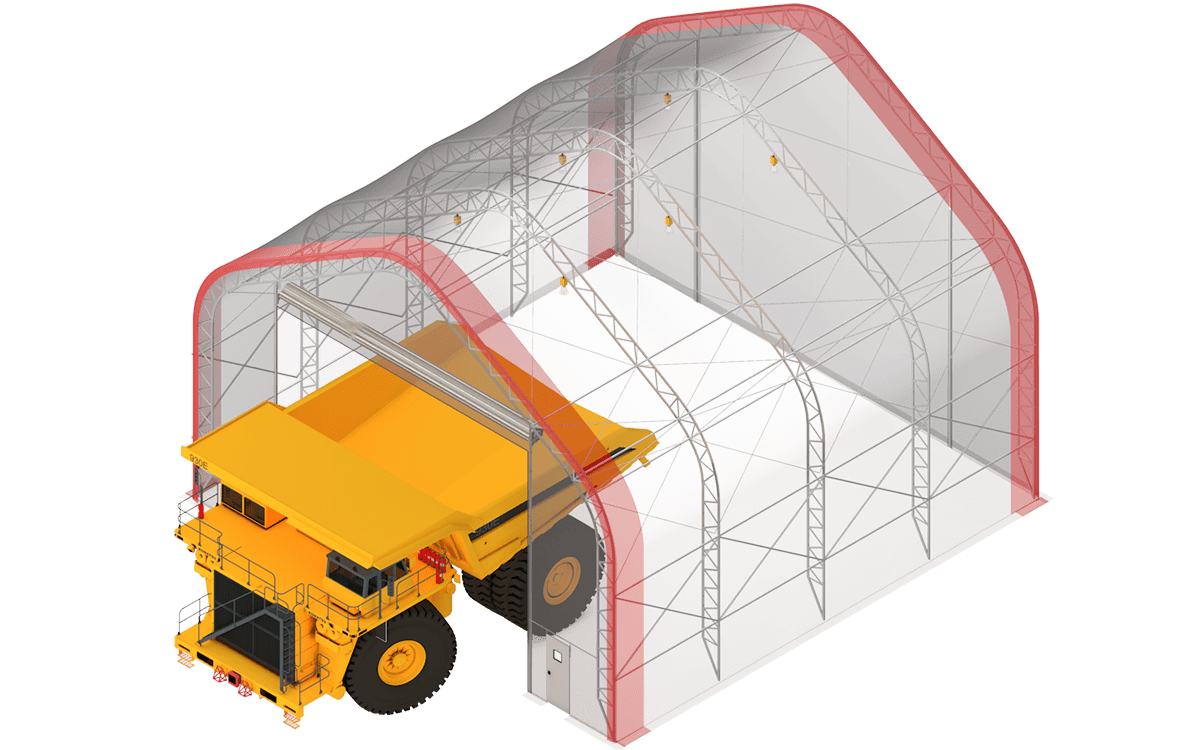

One variable you can control is your machinery’s exposure to the elements. If you store your heavy equipment indoors, the weather can’t hurt it. Alaska Structures makes engineered fabric structures that are easy and quick to assemble with minimal skill. The portable design of their fabric buildings allows them to be used as on-site temporary structures, and easily packed for transportation to the next job site. Engineered fabric structures are the ideal building solution for any operation that needs to relocate regularly. Alternatively, equipment storage facilities and workshops made from fabric structures can be setup, left in place, and used as a great alternative to buildings made using conventional construction methods, including: stick-built structures, brick and mortar construction, metal buildings, or concrete tilt-up facilities.

Specific to maintaining heavy equipment, Alaska Structures has a number of vehicle maintenance and repair facilities that can be custom designed and scaled to accommodate any piece of equipment. A variety of options makes housing a fleet of several hundred work trucks just as easy as opening a sand blasting station for one vehicle, regardless of whether you are working with pickup trucks or a fleet of large mining trucks, like the largest haul truck in the world: the BelAZ 75710.

Unique Advantages of Fabric Buildings From Alaska Structures

Compared to other portable building products, engineered fabric structures from Alaska Structures provide a number of unique advantages:

- Engineered for rapid setup with minimal skill. No expensive special contractors, setup crew, or supervisors required for the installation.

- Minimal foundation requirement allows you to assemble and safely anchor the building system on any level surface including: dirt, gravel, sand, concrete slab, footers, or wood pilings.

- A free span design eliminates the need for interior support columns and maximizes the available interior space.

- High-strength galvanized steel or aircraft-grade aluminum frame systems can be custom designed up to 120’ wide, adjusted to any height, and to any specified length.

- Long-lasting membrane systems offer a much lower life-cycle cost than other tensioned fabric covers.

- The architectural membranes from Alaska Structures are engineered to have a higher resistance to abrasion, will not rot, are mold and mildew resistant, and exceed the fire safety requirements outlined in the California Code of Regulations for membrane structures.

- Proprietary insulation increases energy efficiency to create and maintain a comfortable internal temperature, even in areas with extreme hot and cold climates.

- Translucent sky light material allows you to utilize natural light during the day, creating a bright and safe work environment, while reducing energy usage and cost.

- Plug-and-play lighting and electrical systems available in 50 Hz and 60 Hz reduce the need for expensive electricians1.

- Custom designed to meet your building specification with a large selection of equipment doors, personnel doors, windows, insulation packages, HVAC, and air distribution systems, and vehicle exhaust systems.

- Choose from the largest selection of fabric colors and patterns.

- Add your company logo to any Alaska Structures building.

Whatever your heavy equipment business or operation, Alaska Structures can provide you with an exceptional custom-designed fabric workshop and/or equipment storage building!

Call +1-907-344-1565 today to speak with one of our knowledgeable building specialist! Or send us an email, or contact us online.

¹ A certified electrician may be required to connect the electrical distribution panel to shore power or local power utility. Please check with your local or state requirements.

Leave a Reply