Key Takeaways

- Material Quality Matters – Opt for robust frames like galvanized steel or high‑strength aluminum and durable fabric membranes to ensure structural integrity and longevity.

- Foundation & Anchoring Needs – Choose foundation or anchoring systems (e.g., concrete pads, earth anchors, ballast) tailored to your site’s terrain and expected forces.

- Engineered Design Proven by Testing – Prioritize manufacturers whose designs undergo third-party testing to validate durability under real-world conditions.

- Weather Resilience Is Crucial – High‑end tension fabric structures should withstand extreme elements—snow, wind, heat, UV exposure, mold, and fire—while resisting corrosion and abrasion.

- Code Compliance & Safety – Ensure the structure meets the International Building Code (IBC) and any local regulations for safety and performance requirements.

- Energy Efficiency & Versatility – Leverage insulation, HVAC options, customizable accessories (doors, lighting, flooring), and energy‑saving features to enhance comfort and adaptability.

In recent years, a wave of new technology and innovation in the design and engineering of tension fabric structures has made these modular buildings far more popular for industrial and commercial uses.

Fabric-covered buildings offer a cost-effective alternative to traditional brick-and-mortar buildings in almost any application. Most provide durable, long-lasting shelter and residential, commercial, and industrial facilities.

However, there are a number of manufacturers of heavy-duty fabric structures, so there are several important things to consider before buying a tension fabric building.

1) Strength of materials

Since it’s being used as an alternative for or in replacement of a brick-and-mortar building, a fabric structure must provide reliable shelter relative to that of a normal building. A fabric building’s strength and durability come down to its materials.

Poorer-quality metals and thin-gauge steel frames could cause buckling or excess flexing, which could completely compromise the structure and even lead to catastrophic building collapse. Galvanized steel is the optimal framing material for fabric structures, followed by the more lightweight option of high-strength aluminum.

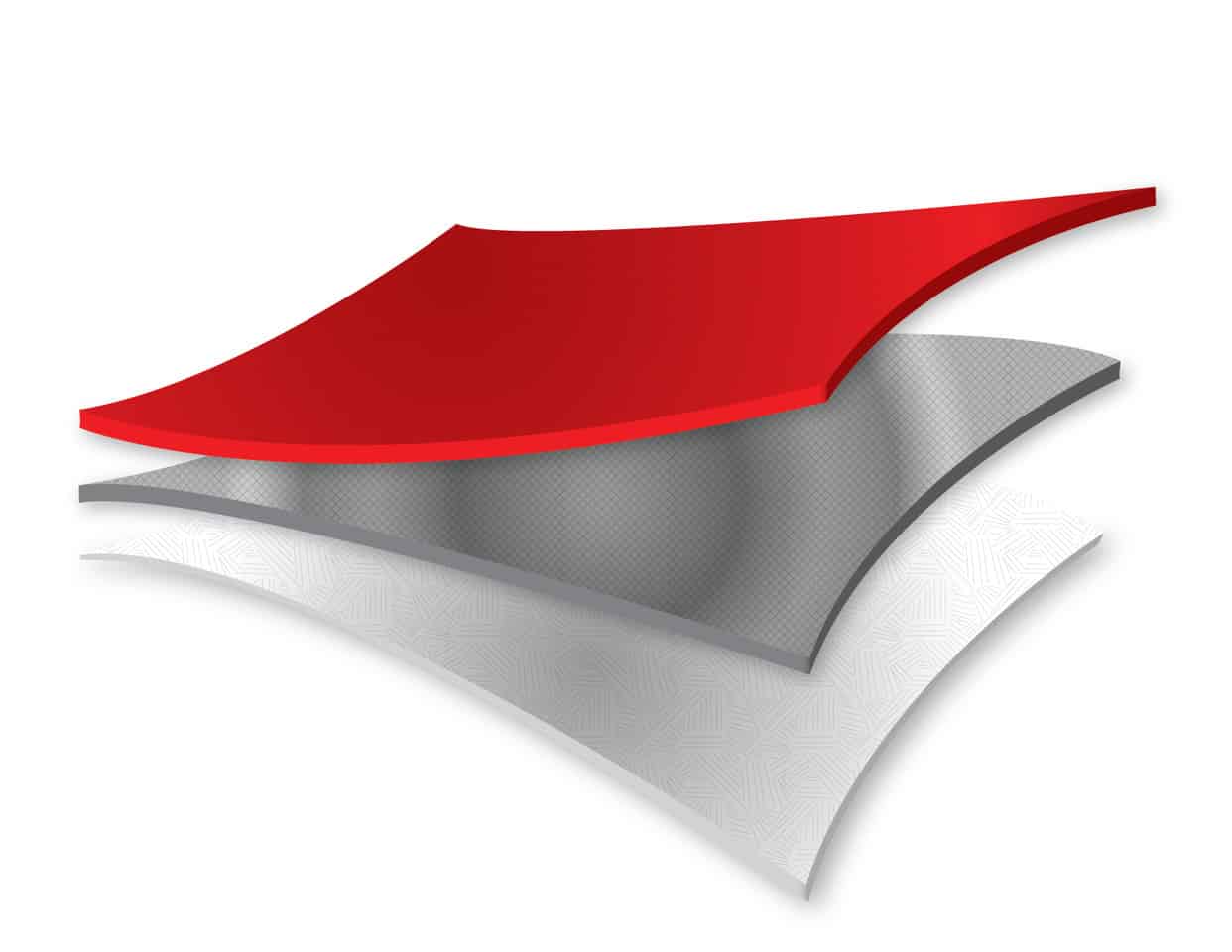

The frame is enclosed by a tension fabric material made from polyvinyl thermoplastic.

2) Foundation requirements

The location, climate, and applicational use for a fabric building will determine the appropriate foundation options. Fabric buildings can be secured to a variety of foundation options, provided the ground is relatively level and flat.

Concrete, wood, and gravel/earth pad foundations are common, but a fabric structure can also be secured directly into the ground using an assortment of anchoring systems.

Some of the most popular anchoring systems include spikes, duckbill earth anchors, lag bolts, concrete wedge anchors, and ballast bars for weight anchors. Bracing with these materials will provide the building with multidimensional strength to counteract tension.

3) Proven building design and engineering

Like any building, a fabric structure requires a financial investment that is lost if it cannot withstand poor weather conditions or long-term use.

While many fabric building manufacturers advertise durability and longevity with their products, it helps to know that your purchase will last with more certainty.

Alaska Structures® designs fabric buildings that are independently tested in the field by third-party companies to provide unbiased assurance of the fabric buildings’ effectiveness, durability, and longevity.

4) Resilience in extreme weather

One of the primary perks of high-end fabric structures is their incredible capacity for resilience under the effects of harsh weather and extreme climates.

Top-of-the-line fabric buildings, such as the modular building systems Alaska Structures® manufactures, can sustain snow loads, high winds, heavy rain and even for extended periods in hazardous environments. The superior fabric membrane, when tensioned properly, is designed for optimal abrasion resistance, will not rot, is mildew and mold resistant, UV stabilized for prolonged exposure to high solar loads, engineered to withstand extreme hot and cold temperatures, chemically inert, and can be ordered to meet the California Code of Regulations to exceed the fire safety requirements for membrane structures. The high-strength frame systems of our pre-engineered fabric buildings are available in galvanized steel or aircraft grade aluminum. Optional powder coating is available in select colors for an added level of protection against rust, salt air, oxidation, humidity, and other environmental factors, thereby increatsing the durability and lifespan.

5) Meeting building codes

All of our fabric buildings meet the standards of International Building Codes (IBC) for safety, and can also be designed to satisfy additional area-specific building code requirements.

If your location has mitigating circumstances that require additional safety and security precautions with your buildings and systems, a specially-designed fabric building may be a preferred, while drastically reducing the time to construct a traditional building.

6) Energy efficiency

Alaska Structures® offers energy-saving insulation options, increasing the overall efficiency of tensile fabric structures and help maintain comfortable interior temperatures.

Our fabric structures are incredibly energy efficient in a range of ways. We offer additional insulation systems to offer any R-value of resistance to thermal energy, reducing energy consumption even further and improving the efficiency of the internal environment and HVAC systems.

7) Versatility of use

Today’s fabric buildings can accommodate far more applications than mere storage facilities or carports, with a near-endless variety of customizations, they offer flexibility in building design, size, and functionality.

Available with a large selection of customizable features, including insulation, windows, personnel doors, equipment doors, lighting and electrical systems (50 and 60 Hz), power generation and distribution systems, modular raised flooring, and mil-spec HVAC units, a pre-engineered fabric structure can be configured to meet your specific building needs, and is often a more ideal alternative to any traditional building.

In industrial and commercial applications, our fabric structures are commonly used as storage facilities and for onsite warehousing, maintenance and reapir facilities, modular buildings for workforce housing, hygiene facilities and mine drys, kitchen and dining facilities, overland conveyor enclosures, core storage facilites (aka “core shacks”), drive-through medical testing and vaccination centers, as well as mission critical facilities like edge data centers.

Some common industries that use Alaska Structures® fabric buildings include oil & gas, mining and mineral exploration, Arctic exploration and research, industrial storage and warehousing, public works, construction, and renewable energy.

8) Add-on components

With such versatility for applicational use of these buildings, the variety of additional systems and features is unsurprisingly vast. You can configure your tension fabric building system with anything from simple cots for housing personnel in an expeditionary setting to furniture packages capable of matching the quality and level of accommodations at a high-end hotel.

Alaska Structures® offers many options for add-on components, including heating, environmental control, lighting and electrical systems, retractable fabric buildings, modular raised flooring for uneven terrain, and portable hygiene solutions, to name a few.

Alaska Structures® excels in each of these areas, providing an ideal option when considering the purchase of a single tension fabric building or a multi-building camp system.

For more information or to order your Alaska Structures® fabric buildings today, call +1-907-344-1565, or contact us online.

Leave a Reply