The waste management industry has been challenged lately with China’s ban on waste imports. Now, more than ever, it’s imperative that waste management facilities quickly expand to efficiently process and handle the millions of tons of waste are piling up. Improving or expanding waste management facilities with engineered fabric structures is one of the many innovative ways to help solve the growing waste problem.

Waste Reduction Increases Waste Storage Facility Efficiency

It’s unrealistic to think that as a modern society, zero waste is achievable, but reducing waste is a good starting place. Storage is one of the most pressing problems, and when a waste storage facility fills to 80 to 85 percent of capacity, the efficiency drops and more space is needed. Finding space is the problem; no one wants a landfill in their backyard, commonly referred to as NIMBY, for “not in my backyard.

The waste management in a Croaita was recently revamped to enable them to overhaul their landfills. In addition to a public service campaign encouraging recycling, the project provided:

- Waste separation at collection areas

- Three new transfer stations

- An integrated waste management center that includes an ecological landfill and a treatment plant that manages 150,000 tons of biodegradable waste per year

- Seven waste collection centers for bulky waste such as electrical equipment and hazardous waste

The overarching goal of this project is to reduce the amount of waste that goes to landfills.

Turn Organic Waste into Fuel

Anaerobic digestion of the organic parts of solid waste is another technology designed to keep landfills from overflowing. The products of this digestion are biogas and organic residue. The biogas can be used as a substitute for natural gas and can be used to produce electricity and heat. The solid residue is known as a “digestate” and can function as fertilizer and compost.

Besides producing alternative fuels, anaerobic digestion also reduces greenhouse gas emissions and ⎼ perhaps most importantly ⎼ keep organic solid waste out of the landfills. Anaerobic digestion is used all over the world as part of a global initiative to reduce methane emissions.

Reduce Recycling Program Risks

There is risk involved with the implementation of a recycling program, and some of those risks are financial. Most risks are in the form of cost overruns, increased overhead, and maintenance costs. To reduce risk, select only proven and reliable technologies.

The project design and operating criteria must be able to:

- Screen for hazardous materials

- Separate biomass and recyclables from other waste

- Provide screening measures for hazardous waste

- Store additional air emission equipment

The Benefits of Tensioned Fabric Buildings in Waste Management

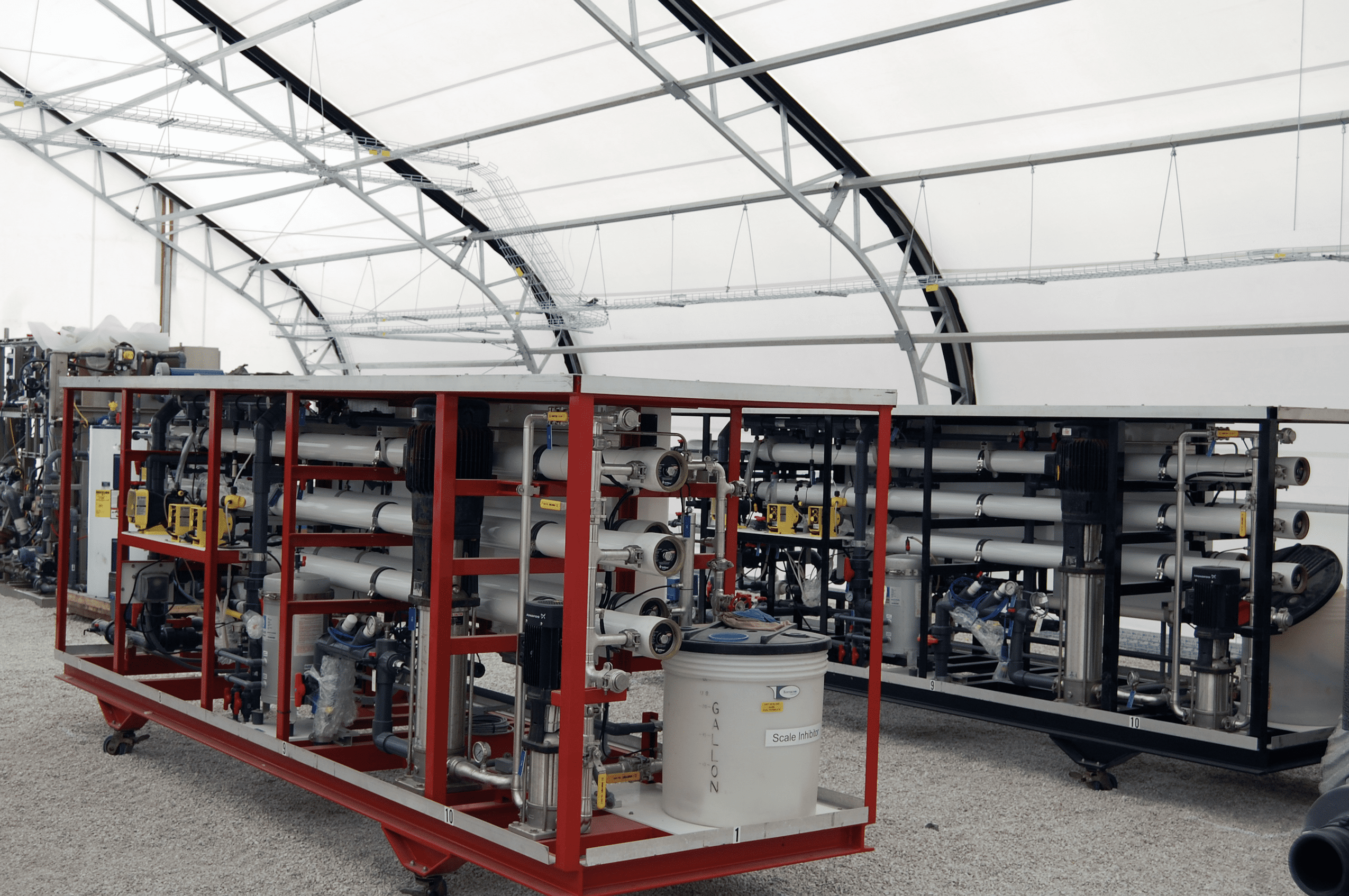

Engineered fabric buildings from Alaska Structures® provide solutions to help waste management companies address the items above. Our modular buildings have shorter construction schedules, with quick, economical shipping and easy setup, with or without our crews. Minimal foundation requirements mean that the buildings can be set up on any level surface with a lower environmental impact. With over 40 years of proven experience and customers in more than 85 countries worldwide, we have proven and reliable building technology for waste management companies needing to quickly expand and increase waste processing or waste storage facilities.

Alaska Structures fabric buildings can be customized to meet the needs of any waste management facility requirement, no matter the size. The DAGB series of gable truss buildings are well-suited for use as waste management facilities. The DAGB buildings can be designed up to any width or length, ensuring coverage for your entire facility. For smaller waster storage needs, such as waste separation areas, hazardous material screening, or air emission equipment, the GB series is a good choice.

Our buildings are constructed with free-span architectural support systems, allowing trucks and equipment easy access and operation within the waste management facility. Alaska Structures uses proprietary tensioned membranes and high-strength aluminum or galvanized steel frames. Our membranes offer a greater abrasion than other polyvinyl- or polyethylene-based fabric covers, are UV stabilized for use in locations with high solar loads, will not rot, are resistant to mold and mildew, and are designed to withstand prolonged use in extreme climates, with temperatures as low as -60˚F (-51.1˚C) and as hot as +130˚F (54.4˚C).

Our engineered fabric structures are portable, and can be easily expanded, reconfigured, or relocated as the waste facility needs change or grow. Once setup, engineered fabric buildings from Alaska Structures are virtually maintenance free – saving your organization from timely and expensive upkeep association with conventional buildings.

For waste processing facilities in remote locations, or deployed as part of a remote work camp, or workforce housing and accommodations, the HGB Series™ of fabric structures are perfect for providing shelter and facilities for employees. The HGB Series™ comes with several standard layout options offering multiple square footage room choices. Our fabric structures offer an interior space that is 24 feet (7.32m) wide and available in multiple lengths. Our plug-and-play lighting and electrical systems are pre-built and allow general laborers the ability to install them without the need for expensive electricians¹. Optional HVAC systems are designed to keep work crews comfortable no matter the weather.

Alaska Structures fabric buildings are engineered for durability and longevity, providing your waste management facility with decades of low-maintenance performance. Call us today to speak with one of our friendly building specialists and discuss your waste processing or storage facility needs.

- Call us at: +1-907-344-1565

- Email us

- Use our online contact form

¹ A certified electrician may be required to connect the electrical distribution panel to shore power or local power utility. Please check with your local or state requirements.

Leave a Reply